Drum gear couplings have a high ability to withstand bending moments, but their specific performance is influenced by various factors. When selecting and using, it is necessary to fully consider factors such as design characteristics, material selection, manufacturing accuracy, and working environment, and take corresponding measures to improve its ability to withstand bending moments.

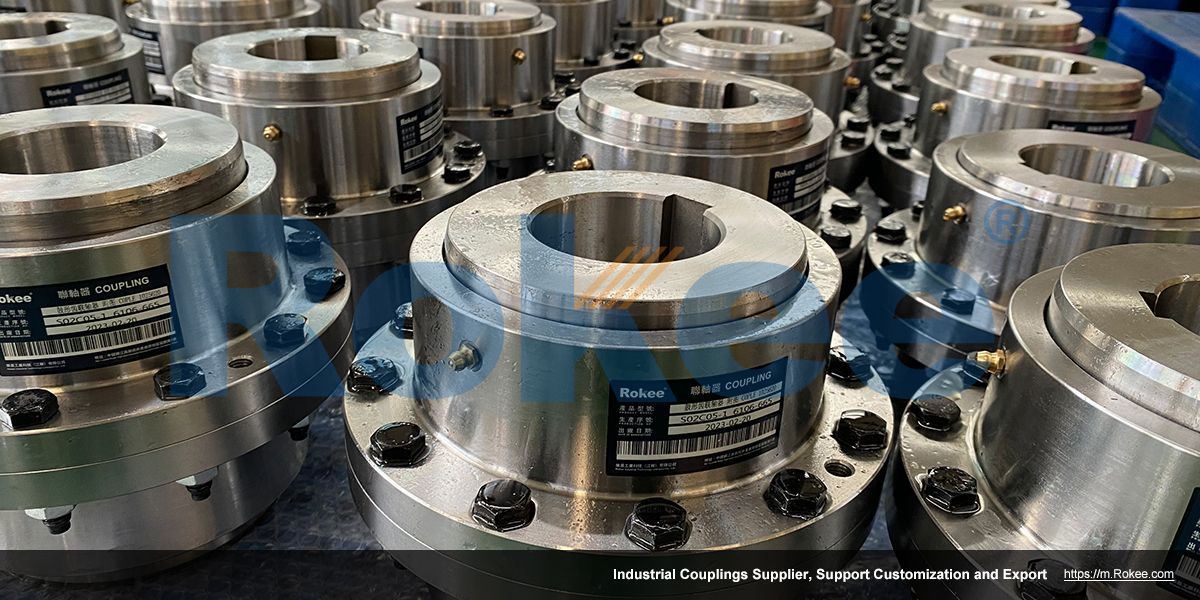

The drum toothed coupling is composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. Among them, the outer teeth are made into a spherical shape, with the center of the sphere on the gear axis, and the tooth flank clearance is larger than that of ordinary gears. This design improves the contact conditions of the transmission teeth, extends the service life, and enables the drum tooth coupling to have greater angular displacement compensation capability compared to the straight tooth coupling.

The crown gear coupling has a high load-bearing capacity, thanks to its unique design and manufacturing process. However, its ability to withstand bending moments is also influenced by various factors, as follows:

Material selection: Excellent materials have good toughness and strength, and can withstand greater torque and load. Choosing materials with high toughness and strength, such as alloy steel, stainless steel, etc., can significantly improve the bending moment bearing capacity of drum gear couplings.

Design parameters: tooth profile, modulus, tooth width, number of teeth, and other design parameters will affect the bending moment capacity of the drum gear coupling. Correct design parameters can optimize tooth contact conditions and enhance load-bearing capacity. For example, by optimizing the tooth profile, increasing the modulus and tooth width, and correctly arranging the number of teeth, the contact conditions of the tooth surface can be improved, thereby enhancing the bending moment bearing capacity of the drum gear coupling.

Manufacturing accuracy: Manufacturing accuracy also has a significant impact on the bending moment capacity of drum gear couplings. If the manufacturing accuracy is not high, such as large tooth profile errors, tooth surface roughness not meeting requirements, etc., it will cause local stress concentration in the coupling under normal working loads, reducing its actual bending moment bearing capacity.

Working environment: harsh environments such as high temperature, high pressure, and corrosive media can accelerate the wear and aging of couplings, reducing their ability to withstand bending moments. Therefore, when selecting and using drum gear couplings, it is necessary to fully consider the impact of their working environment and take corresponding protective measures.

In order to improve the bending moment bearing capacity of the drum gear coupling, the following measures can be taken:

Optimize design and material selection: Based on specific application scenarios and requirements, optimize design parameters and select materials with high strength and toughness.

Improve manufacturing accuracy: Adopt advanced manufacturing processes and equipment to ensure that the tooth profile accuracy and tooth surface roughness meet the requirements.

Strengthen maintenance: Regularly inspect and maintain the drum gear coupling, promptly identify and address potential issues, and extend its service life and bending moment capacity.

Drum teeth couplings are widely used in industries such as metallurgy, mining, and lifting transportation due to their excellent performance characteristics. They are also suitable for shaft transmission in various types of machinery such as petroleum, chemical, and general machinery. With the continuous development of manufacturing and technological advancement, drum gear couplings will be applied in more fields and demonstrate greater market potential.

« Drum Gear Coupling Bears Bending Moment » Post Date: 2023/8/28

URL: https://m.rokee.com/blog/drum-gear-coupling-bears-bending-moment.html

- Add Springs Inside The Drum Gear Coupling

- Disadvantages Of Drum Gear Coupling

- Accuracy Requirements For Drum Gear Couplings

- Dimensions Related To Drum Gear Couplings

- Acceptance Standards For Drum Gear Couplings

- Selection Of Drum Gear Coupling

- Abnormal Sound From Drum Gear Coupling

- Service Life Of Drum Gear Coupling

- Shaft End Dimensions Of Drum Gear Coupling

- Shape Of Drum Gear Coupling