The balance performance of drum gear couplings is crucial for the stability and reliability of mechanical systems. By improving design and manufacturing accuracy, strengthening quality control during installation and commissioning, and conducting regular maintenance and upkeep, measures can be taken to ensure that the crown gear coupling maintains a good balance state, thereby extending the service life of the mechanical system and improving operational efficiency.

The performance of drum tooth couplings in terms of balance mainly depends on their design and manufacturing accuracy, as well as maintenance during use.

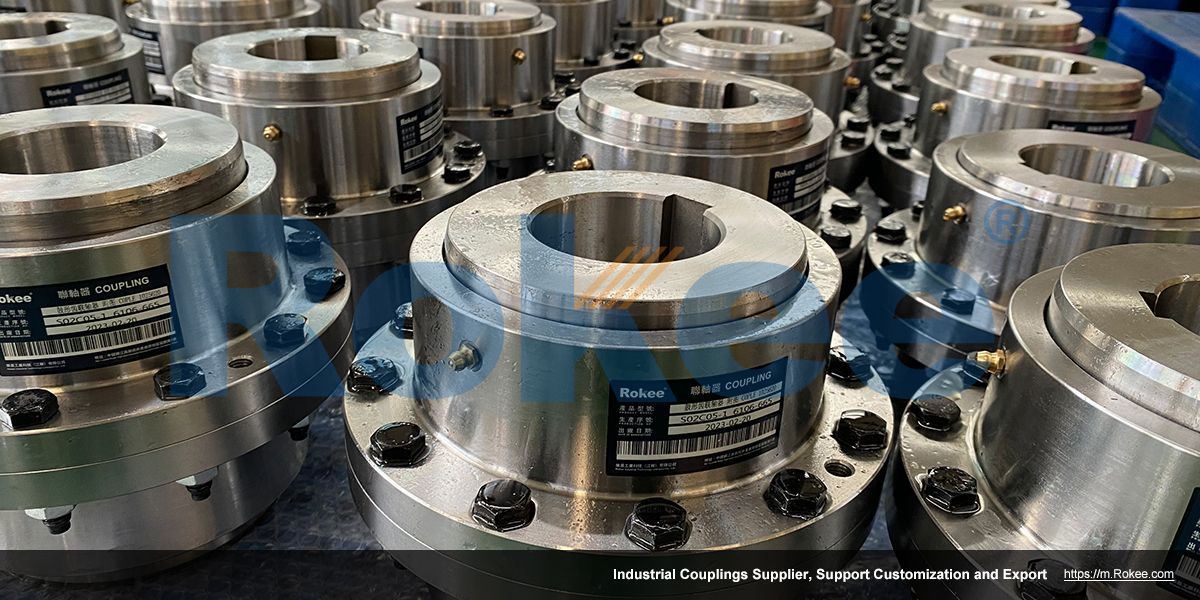

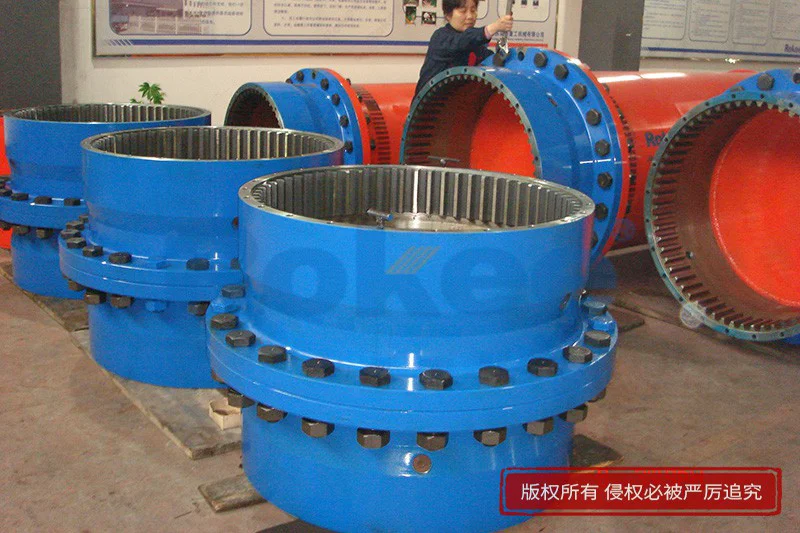

Drum gear coupling belongs to rigid flexible coupling, consisting of internal gear rings with the same number of teeth and flange half couplings with external teeth. Among them, the outer teeth are made into a spherical shape, with the center of the spherical surface on the gear axis. This design allows for a larger backlash between the teeth compared to general gears, allowing for greater angular displacement, improving the contact conditions of the teeth, enhancing the ability to transmit torque, and extending the service life.

Balance is crucial for any rotating machinery. Imbalance can lead to vibration, noise, bearing wear, and premature damage to mechanical components. As an important component of mechanical transmission, the balance state of the drum toothed coupling directly affects the stability and reliability of the entire mechanical system.

Balance measures for drum gear coupling

Design and Manufacturing Accuracy:

In the design phase, it is necessary to ensure the structural symmetry of the coupling to reduce imbalance factors.

During the manufacturing process, the machining accuracy should be strictly controlled to ensure that the dimensions and shapes of each component meet the design requirements.

Perform dynamic balance testing on the coupling to eliminate unbalanced mass.Installation and Debugging:

During installation, it should be ensured that the axis of the coupling coincides with the axis of the equipment to reduce imbalance caused by installation errors.

During debugging, the operation of the coupling should be checked. If there are any abnormal vibrations or noises, they should be adjusted in a timely manner.Maintenance and upkeep:

Regularly check the wear of the coupling and replace severely worn components in a timely manner.

Keep the coupling and its surrounding environment clean to prevent debris from entering the interior of the coupling.

Lubricate the coupling to reduce friction and wear.

High precision and dynamically balanced drum gear couplings can be used for high-speed transmission, such as shaft transmission in gas turbines. In these applications, the balance state is directly related to the stability and safety of the mechanical system. Therefore, for high-precision drum teeth couplings, more attention should be paid to the detection and maintenance of their balance performance.

« Drum Gear Coupling Balance » Post Date: 2023/8/28

URL: https://m.rokee.com/blog/drum-gear-coupling-balance.html

- Working Condition Coefficient Of Drum Gear Coupling

- Drum Gear Coupling Forward And Reverse

- Drum Gear Coupling Direct Pin

- Working Condition Of Drum Gear Coupling

- Drum Gear Coupling Deflection Angle

- Drum Gear Coupling Connecting Bolts

- Working Principle Of Drum Gear Coupling

- Drum Gear Coupling Code

- Drum Gear Coupling Centering Ball

- Worn Drum Gear Coupling