Drum gear couplings have many advantages and have broad application prospects in the field of mechanical transmission. However, it also has some drawbacks and limitations that need to be considered and addressed in specific applications.

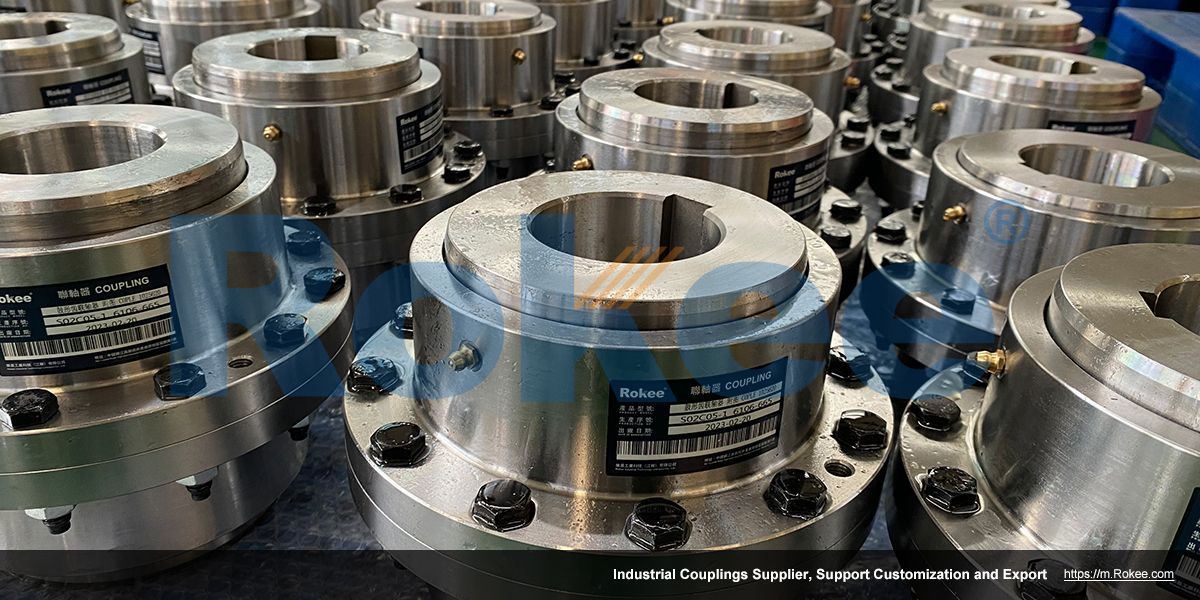

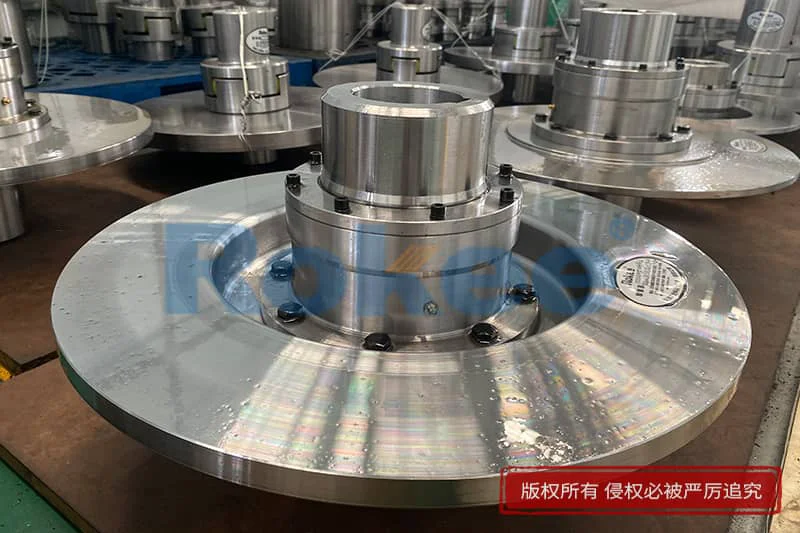

Drum gear coupling as an important mechanical transmission component, plays a crucial role in various types of mechanical equipment.

Advantages of Drum Gear Coupling

Strong load-bearing capacity: The crown gear coupling has an average load-bearing capacity that is 15% to 20% higher than the straight tooth coupling under the same outer diameter of the inner gear sleeve and the larger outer diameter of the coupling. This is due to its drum shaped tooth surface design, which improves the contact conditions between the inner and outer teeth, thereby enhancing the ability to transmit torque.

Large angular displacement compensation: Drum gear couplings allow for larger angular displacements and have stronger angular compensation capabilities compared to spur gear couplings. This makes the drum toothed coupling significantly advantageous in dealing with axis deviations.

Low noise and long maintenance cycle: Due to the improved friction and wear condition of the drum shaped tooth surface design, the noise generated by the drum shaped tooth coupling during operation is relatively low. At the same time, this also extends its maintenance cycle and reduces maintenance costs.

Compact structure and high transmission efficiency: The drum gear coupling has the characteristics of compact structure and small turning radius, which makes it widely used in space limited situations. In addition, its transmission efficiency is as high as 99.7%, ensuring the stability and efficiency of mechanical transmission.

Easy to assemble and disassemble: The outer tooth sleeve of the drum gear coupling has a trumpet shaped tooth end, which makes the assembly and disassembly of the inner and outer teeth very convenient and improves work efficiency.

Disadvantages of Drum Gear Coupling

High rigidity, no elasticity: Drum tooth couplings have high rigidity but lack elasticity. Therefore, it is not suitable for mechanical equipment that requires vibration reduction and buffering. In machinery with strict requirements for two axis alignment, drum gear couplings may also not be able to meet the demands.

Tooth surface wear: Although the design of the drum shaped tooth surface improves the friction condition of the tooth surface, tooth surface wear is still an inevitable problem. Long term work can lead to increased wear on the tooth surface, thereby affecting the service life and transmission efficiency of the coupling.

Transmission noise: Although the noise of drum gear couplings is relatively low, certain transmission noise may still be generated in certain high load or high-speed operating situations. This requires regular maintenance and upkeep of the coupling to reduce noise generation.

Lubrication requirement: Drum toothed couplings require lubricating oil to be added during operation to reduce tooth wear and power consumption. However, this also increases the pollution process and maintenance costs.

Pulsating impact: Due to the large circumferential clearance (between teeth) of the drum gear coupling transmission, pulsating impact is prone to occur in some cases. This may have adverse effects on the stability and service life of mechanical equipment.

« Advantages And Disadvantages Of Drum Gear Coupling » Post Date: 2023/8/14

URL: https://m.rokee.com/blog/advantages-and-disadvantages-of-drum-gear-coupling.html

- Working Principle Of Industrial Toothed Couplings

- Axial Compensation Amount Of Drum Gear Coupling

- Toothed Coupling Of Water Supply Pump

- Tipper Gear Coupling

- Axial Clearance Of Drum Gear Coupling

- Steel Toothed Coupling

- Steel Ball Toothed Coupling

- Assembly Tolerance Of Drum Gear Coupling

- Standard For Industrial Toothed Couplings

- Standard For End Face Toothed Couplings