The Crane Drum Coupling is an important part in the transmission system of crane equipment. It connects the power input shaft of the reducer with the drum, transmits torque and restricts the axial movement of the drum at the same time. It also has mechanical or electronic wear alarm, and is one of the core parts of the drum crane mechanism.

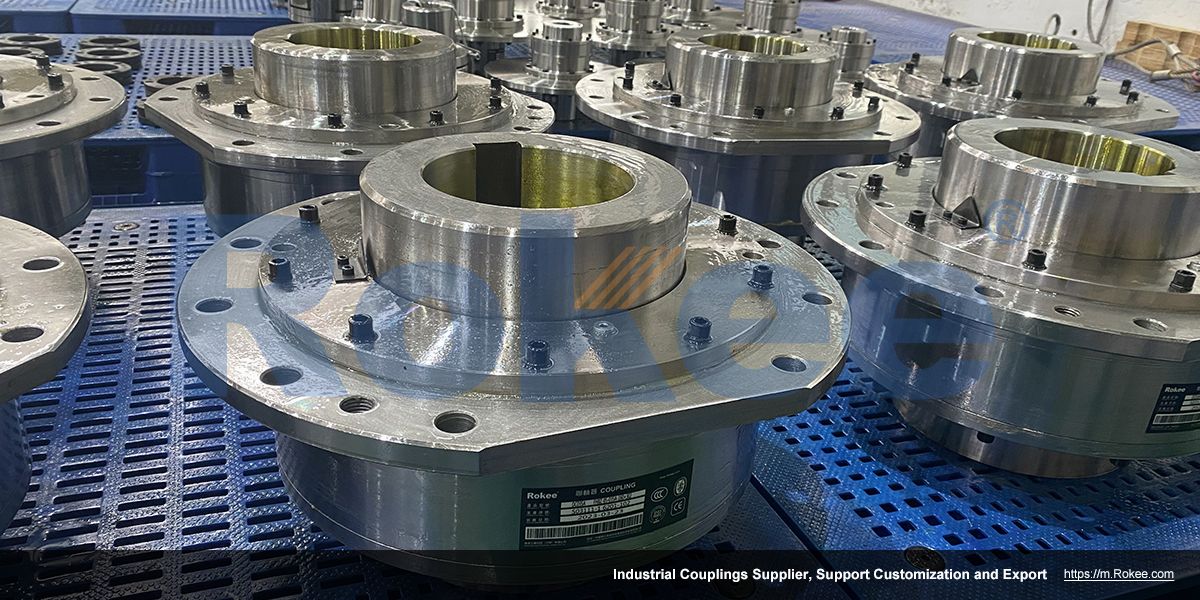

The RWC ball and drum gear drum coupling is a drum coupling developed by Rokee with a more reliable structure, higher compensation ability and higher safety factor. The outer sleeve adopts a spherical drum tooth design, which has low requirements for shafting installation accuracy, large transmission torque, strong overload capacity and can withstand great radial load. The connection size is the same as that of DC series, but the bearing capacity is increased by more than 30%. The innovative spherical sealing technology makes this type of product maintain excellent lubrication and greatly improve its service life.

In the complex ecosystem of industrial machinery, power transmission stands as a fundamental pillar that ensures the seamless conversion and transfer of energy from prime movers to driven equipment. Within this critical domain, couplings play an indispensable role as mechanical connectors, bridging the gap between rotating shafts while accommodating misalignments, absorbing shocks, and mitigating vibrations. Among the diverse array of coupling types available, drum coupling and barrel coupling have emerged as reliable solutions for a wide range of industrial applications, each distinguished by unique structural designs, operational characteristics, and performance capabilities.

To appreciate the functional nuances of drum coupling and barrel coupling, it is essential to first establish a foundational understanding of their core definitions and structural configurations. At their essence, both couplings are engineered to transmit torque between two coaxial or slightly misaligned shafts, but their geometric designs and component arrangements set them apart. A drum coupling typically features a cylindrical drum-shaped element attached to one shaft, which interfaces with a mating component on the other shaft—often a convex or cylindrical surface—creating a contact area that facilitates torque transfer. The drum element, which gives the coupling its name, is usually fabricated from high-strength metallic materials, with precision machining to ensure smooth contact and efficient power transmission. In contrast, a barrel coupling is characterized by a barrel-like, slightly tapered or curved outer surface on one of its coupling halves, designed to engage with a complementary surface on the opposing half. This barrel-shaped design is engineered to enhance the coupling’s ability to accommodate angular and parallel misalignments, making it particularly suitable for applications where shaft alignment is challenging to maintain.

The structural components of drum coupling and barrel coupling further highlight their design differences and functional priorities. A typical drum coupling assembly consists of three main parts: the drum hub, the mating hub, and a connecting element—such as bolts, pins, or a flexible sleeve—that secures the two hubs while allowing a degree of relative movement. The drum hub is the key distinguishing component, featuring a hollow cylindrical structure that may have internal or external teeth, splines, or a smooth surface depending on the torque transmission method. For instance, some drum couplings utilize a friction-based design, where the drum’s inner surface presses against a mating shaft sleeve, relying on frictional force to transfer torque. Others employ a positive locking mechanism, such as splines or keyways, to ensure a more rigid and efficient torque transfer. In comparison, a barrel coupling’s structure is often more integrated, with the barrel-shaped element forming an integral part of one coupling half. The opposing half typically features a concave or tapered surface that mates with the barrel, creating a contact zone that distributes torque evenly across the surface. Many barrel couplings also incorporate flexible elements, such as rubber or elastomeric inserts, between the barrel and the mating surface to enhance shock absorption and vibration damping, while further accommodating misalignments.

The working principles of drum coupling and barrel coupling are rooted in their structural designs, with each leveraging distinct mechanisms to achieve torque transmission and misalignment compensation. For drum couplings, the torque transfer process begins with the rotation of the driving shaft, which imparts motion to the drum hub. Depending on the design, this motion is then transferred to the mating hub either through frictional contact or positive engagement. In friction-based drum couplings, the contact pressure between the drum and the mating surface is crucial—this pressure is often maintained by preloaded bolts or springs, ensuring that the frictional force is sufficient to transmit the required torque without slippage. When misalignment occurs between the driving and driven shafts, the drum’s cylindrical shape allows for a small degree of angular and parallel movement, as the contact area between the drum and the mating component adjusts to accommodate the misalignment. However, the misalignment capacity of drum couplings is generally limited compared to more flexible coupling types, making them better suited for applications where shaft alignment is relatively stable.

Barrel couplings, on the other hand, operate on a principle that emphasizes misalignment accommodation through their curved or tapered barrel surface. As the driving shaft rotates, the barrel-shaped element engages with the complementary surface on the driven hub, transferring torque through a combination of contact pressure and shear forces. The barrel’s curved profile allows for a greater range of angular misalignment, as the contact point between the barrel and the mating surface shifts smoothly as the shafts rotate. This design also enables the coupling to compensate for parallel misalignment by allowing a small amount of axial movement between the two halves. In barrel couplings with flexible elements, the elastomeric inserts absorb shock and vibration by deforming under load, while also providing additional misalignment capacity. This makes barrel couplings particularly effective in applications where the prime mover or driven equipment generates significant vibrations, or where shaft misalignment is unavoidable due to installation constraints or thermal expansion.

The application landscapes of drum coupling and barrel coupling are shaped by their performance characteristics, with each finding optimal use in specific industrial sectors and operating conditions. Drum couplings are widely employed in applications that require high torque transmission, rigid shaft connection, and moderate misalignment compensation. One of the primary application areas for drum couplings is in heavy-duty machinery, such as mining equipment, steel rolling mills, and cement plants. In these environments, the couplings must withstand extreme torque loads and harsh operating conditions, including dust, debris, and temperature fluctuations. The robust construction of drum couplings, typically made from alloy steels or carbon steels, makes them well-suited for these demanding applications. For example, in a steel rolling mill, drum couplings are used to connect the motor to the rolling stands, transmitting the high torque required to deform the steel sheets. Another key application area for drum couplings is in marine propulsion systems, where they connect the ship’s engine to the propeller shaft. The ability of drum couplings to transmit high torque efficiently and accommodate minor misalignments due to hull flexing makes them ideal for this critical application.

Barrel couplings, by virtue of their superior misalignment capacity and vibration damping capabilities, are commonly used in applications where shaft alignment is problematic or where vibration control is essential. One of the most prevalent applications of barrel couplings is in industrial pumps and compressors. These rotating equipment often experience shaft misalignment due to thermal expansion, foundation settling, or improper installation, and the barrel coupling’s ability to accommodate these misalignments helps prevent premature bearing failure and reduce maintenance costs. For instance, in a centrifugal pump system, the barrel coupling connects the electric motor to the pump impeller shaft, absorbing the vibrations generated by the pump’s operation and compensating for any misalignment between the motor and pump shafts. Barrel couplings are also widely used in HVAC systems, where they connect fans and blowers to their drive motors. In these applications, the coupling’s vibration damping properties help reduce noise levels and improve the overall efficiency of the HVAC system. Additionally, barrel couplings find use in agricultural machinery, such as tractors and harvesters, where they must withstand variable torque loads and accommodate misalignments caused by the machinery’s movement over uneven terrain.

When selecting between drum coupling and barrel coupling for a specific application, several key factors must be considered to ensure optimal performance, reliability, and longevity. The first and foremost factor is the torque requirement of the application. Drum couplings are typically capable of transmitting higher torque loads compared to barrel couplings of the same size, making them the preferred choice for heavy-duty applications with high torque demands. Conversely, barrel couplings are better suited for medium to low torque applications where misalignment and vibration are the primary concerns. The second critical factor is the degree of misalignment present between the shafts. If the application involves significant angular or parallel misalignment, a barrel coupling is the more appropriate choice, as its design allows for greater misalignment compensation. In contrast, if the shafts are relatively well-aligned, a drum coupling can provide a more rigid and efficient connection.

Other important selection criteria include the operating speed, temperature, and environmental conditions. Both drum and barrel couplings have specific speed limits, which are determined by their structural design and material properties. High-speed applications, such as those found in turbomachinery, require couplings that can withstand centrifugal forces without excessive vibration or wear—this may favor certain types of drum or barrel couplings with precision-balanced components. Operating temperature is another key consideration, as extreme temperatures can affect the material properties of the coupling components, particularly elastomeric elements in barrel couplings. In high-temperature environments, such as in steel mills or glass manufacturing plants, drum couplings made from high-temperature-resistant metals may be more suitable, while barrel couplings with heat-resistant elastomers may be required for moderate temperature applications. Environmental conditions, such as the presence of dust, moisture, chemicals, or corrosive substances, also influence the selection process. Drum couplings with sealed components or corrosion-resistant coatings are ideal for harsh environments, while barrel couplings with protected elastomeric elements can prevent contamination and extend service life.

Maintenance practices play a vital role in ensuring the long-term performance and reliability of both drum coupling and barrel coupling. Regular maintenance not only extends the service life of the couplings but also helps prevent unexpected failures that can lead to costly downtime. For drum couplings, the primary maintenance tasks include regular inspection of the drum surface and mating components for wear, corrosion, or damage. Friction-based drum couplings require periodic checks of the contact pressure, as loose bolts or worn springs can reduce the frictional force and lead to slippage. Additionally, lubrication is essential for drum couplings with moving parts, such as splines or bearings, to reduce friction and wear. The type of lubricant used should be compatible with the coupling material and operating conditions, and lubrication intervals should be followed strictly to ensure optimal performance.

Barrel couplings require similar maintenance practices, with a particular focus on the flexible elements if present. Elastomeric inserts can degrade over time due to age, temperature, or chemical exposure, so regular inspection for cracks, hardness, or deformation is essential. If the flexible elements are worn or damaged, they should be replaced promptly to prevent excessive vibration and misalignment. The barrel surface and mating components should also be inspected for wear, corrosion, or damage, as uneven wear can affect the coupling’s ability to transmit torque and accommodate misalignments. Lubrication is also important for barrel couplings, especially those with metal-to-metal contact surfaces, to reduce friction and prevent galling or seizing. In addition to regular inspections and lubrication, both drum and barrel couplings should be checked for proper alignment periodically, as misalignment can increase stress on the coupling components and lead to premature failure.

The future development of drum coupling and barrel coupling is closely tied to advancements in materials science, manufacturing technology, and industrial automation. One of the key trends in coupling design is the use of lightweight and high-strength materials, such as carbon fiber composites and titanium alloys, to reduce the overall weight of the coupling while maintaining or improving its torque-carrying capacity. This is particularly important for applications in the aerospace and automotive industries, where weight reduction is a critical factor in improving fuel efficiency and performance. For drum couplings, the use of composite materials in the drum element could reduce inertia and improve dynamic balance, making them suitable for high-speed applications. For barrel couplings, composite flexible elements could offer improved durability and resistance to harsh environmental conditions compared to traditional elastomers.

Another significant trend is the integration of smart technologies into coupling design, enabling condition monitoring and predictive maintenance. Sensors embedded in the coupling components can measure parameters such as temperature, vibration, torque, and misalignment, providing real-time data to operators. This data can be analyzed using machine learning algorithms to detect potential issues before they lead to failure, allowing for proactive maintenance and reducing downtime. For example, a smart drum coupling could monitor the contact pressure and temperature of the drum surface, alerting operators if the pressure drops below a critical level or if the temperature exceeds safe limits. A smart barrel coupling could monitor the condition of the flexible elements and the degree of misalignment, providing early warning of potential failures.

Advancements in manufacturing technology, such as additive manufacturing (3D printing), are also poised to revolutionize the production of drum and barrel couplings. 3D printing allows for the creation of complex geometric shapes that are difficult or impossible to achieve with traditional machining methods, enabling the design of couplings with optimized performance characteristics. For instance, 3D printing can be used to create drum elements with internal cooling channels to dissipate heat in high-temperature applications, or barrel surfaces with customized profiles to enhance misalignment compensation. Additionally, additive manufacturing reduces material waste and allows for rapid prototyping, enabling manufacturers to develop and test new coupling designs more efficiently.

In conclusion, drum coupling and barrel coupling are essential components in power transmission systems, each offering unique advantages and suitable for specific applications. Drum couplings excel in high-torque, rigid-connection applications, while barrel couplings are distinguished by their superior misalignment accommodation and vibration damping capabilities. The selection of the appropriate coupling type depends on a range of factors, including torque requirements, misalignment degree, operating speed, temperature, and environmental conditions. Proper maintenance practices, including regular inspection, lubrication, and alignment checks, are critical to ensuring the long-term reliability and performance of these couplings. Looking to the future, advancements in materials, smart technologies, and manufacturing processes will continue to enhance the capabilities of drum and barrel couplings, making them even more versatile and efficient in meeting the evolving needs of modern industry. As industrial machinery becomes increasingly complex and demanding, the role of these couplings in ensuring reliable power transmission will only grow in importance, underscoring the need for ongoing research and development in this field.