Rokee® Customized Steel Laminae Coupling For Generator System for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

Steel laminae coupling is a high-performance flexible coupling that compensates for relative displacement between connecting shafts through the elastic deformation of metal diaphragms. The core working principle is to use one or more sets of precision machined metal diaphragms, which can effectively absorb and compensate for axial, radial, and angular deviations while transmitting torque, ensuring the smooth operation of the transmission system.

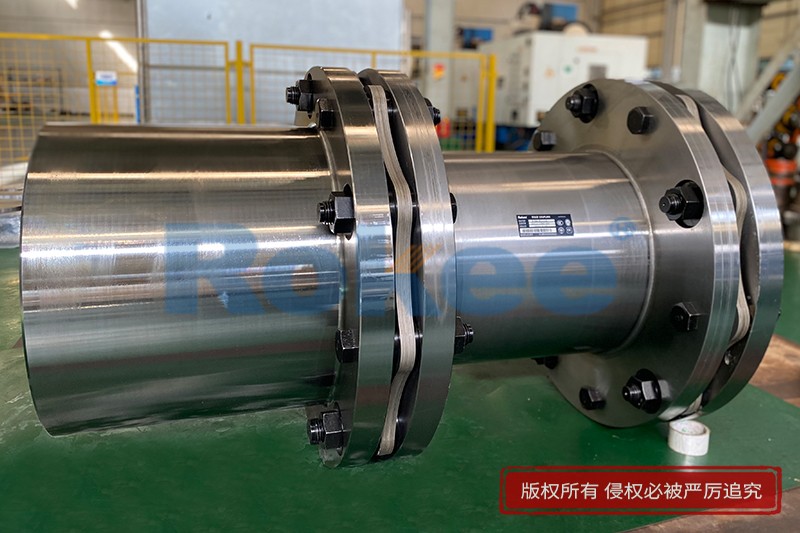

Structurally, the steel laminae coupling is mainly composed of the following parts:

Metal diaphragm group: usually made of stainless steel or high-strength alloy steel, it is the core elastic element of the coupling

Wheel hub: a key component that connects the drive shaft and the driven shaft

Intermediate sleeve (available on some models): used to connect two sets of membranes to increase compensation capability

Fasteners: high-strength bolts and nuts to ensure reliable connection

Steel laminae couplings can be divided into two categories: single diaphragm type and double diaphragm type. The single steel laminae coupling has a simple and compact structure, suitable for medium power and medium speed applications; Double steel laminae couplings have higher deviation compensation and torque transmission capabilities, making them suitable for applications with high power, high speed, or high centering requirements.

Compared with traditional couplings, steel laminae couplings have several significant advantages:

Zero backlash transmission: ensures precise torque transmission and avoids impact vibration caused by clearance in traditional couplings

Maintenance free design: No lubrication required, reducing downtime and maintenance costs

High torsional stiffness: ensuring transmission accuracy, especially suitable for precision transmission systems

Long service life: The metal diaphragm has excellent fatigue resistance and a service life of tens of thousands of hours

Lightweight design: Compared to traditional types such as gear couplings, the weight is significantly reduced

In the generator system, the steel laminae coupling is mainly used to connect the prime mover (such as turbine, gas turbine or diesel engine) with the generator, and its core functions include:

Torque transmission: Efficiently and reliably transmit the rotational power of the prime mover to the generator

Deviation compensation: compensating for installation alignment errors and thermal expansion deformation during operation

Vibration isolation: reduce the transmission of vibration from the prime mover to the generator and protect the generator bearings

Overload protection: Under abnormal working conditions, the diaphragm can provide certain overload protection

The key points for selecting steel laminae couplings in generator systems include:

Torque capacity: must meet the requirements of maximum operating torque and instantaneous overload torque of the system

Speed range: Suitable for the working speed of the generator system, including critical speed analysis

Deviation compensation capability: Determine the required compensation amount based on installation accuracy and operational deformation

Environmental adaptability: Consider the impact of environmental factors such as temperature, humidity, and corrosion

Inertia matching: The rotational inertia of the coupling should be matched with other components of the system

As a key transmission component in generator systems, steel laminae couplings are widely used in wind power, hydropower, gas turbine power generation and other fields due to their high reliability, maintenance free and excellent compensation capabilities. With the advancement of materials science, manufacturing processes, and monitoring technology, the performance of steel laminae couplings will be further improved, and their application scope will continue to expand. For generator system designers and users, the reasonable selection and correct use of steel laminae couplings are of great significance for improving system reliability and reducing maintenance costs.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/steel-laminae-coupling-for-generator-system.html