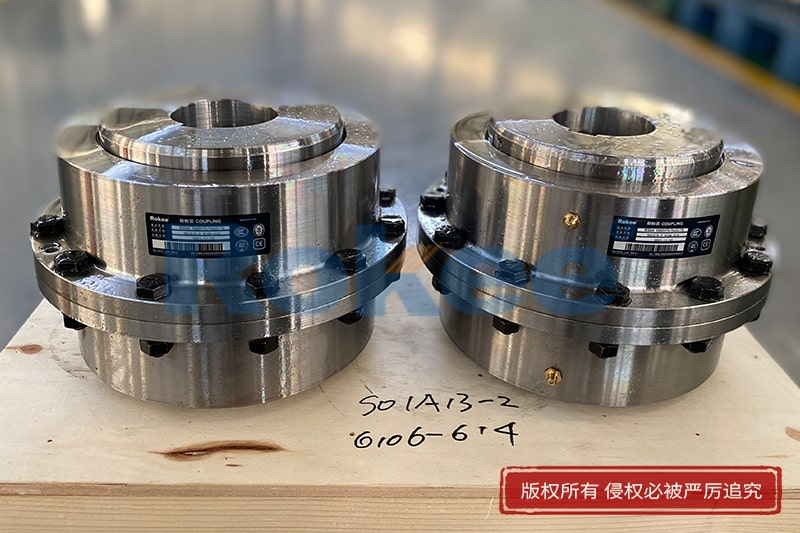

Rokee® Customized RODA Gear Type Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

RODA gear type coupling is an innovative rigid flexible coupling device, consisting of a precision matched inner gear ring and a flange half coupling with outer teeth at its core. Compared with traditional spur gear couplings, its revolutionary design lies in the use of spherical drum shaped external teeth, with the tooth surface forming a circular arc shape centered on the gear axis, while increasing the tooth flank clearance. This special structure is not a simple form change, but an engineering optimization based on complex force analysis, which enables the coupling to achieve multi tooth simultaneous contact during transmission, significantly improving load distribution.

The core advantages are reflected in two aspects:

Improved compensation capability: The increased tooth flank clearance allows for greater axial (maximum ± 15mm), radial (maximum ± 5mm), and angular displacement compensation (maximum 2.5 °), which increases the compensation capability by more than 50% compared to spur gear couplings

Load distribution optimization: The drum shaped tooth surface design increases the meshing contact area by 30% -50%, avoiding the squeezing phenomenon of the tooth end edges of the straight tooth coupling, and extending the theoretical life by 50% -100%

Structural design features

Spherical drum shaped tooth profile: The outer gear sleeve tooth top is machined into a spherical surface, and the curvature radius of the indexing circle is precisely matched with the thinning amount of the inner teeth, eliminating the risk of interference

Modular components: using shell mold forming technology to achieve separation and processing of inner and outer gear rings (with an accuracy of IT6 level), with a hole diameter range covering 16-1200mm

Lubrication system: Equipped with a dual seal structure as standard, with optional forced thin oil lubrication (filtration accuracy<10 μ m) or segmented grease lubrication to ensure a transmission efficiency of 99.7%

Standard series classification

RODA basic model: standard transmission scenario, torque coverage 1900-2860000Nm

RODP brake disc type: integrated DIN15435 standard brake disc interface, suitable for lifting equipment

RODX intermediate shaft type: floating shaft design, transmission distance can be extended to 5 meters

RODV vertical installation type: special seal to prevent grease leakage, tilt compensation up to 3 °

RODM torque protection type: mechanical overload protection, adjustable setting range ± 5%

Typical application areas

Heavy industry: metallurgical rolling mill (hot rolling mill torque up to 8 × 10 ⁶ Nm), mining crusher (impact load coefficient 2.5)

Energy equipment: wind turbine gearbox (compensating for impeller deflection of 0.5 °), steam turbine generator set (speed 3600rpm)

Process industry: compressor (axial displacement ± 8mm), ball mill (continuous vibration condition)

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/roda-gear-type-coupling.html