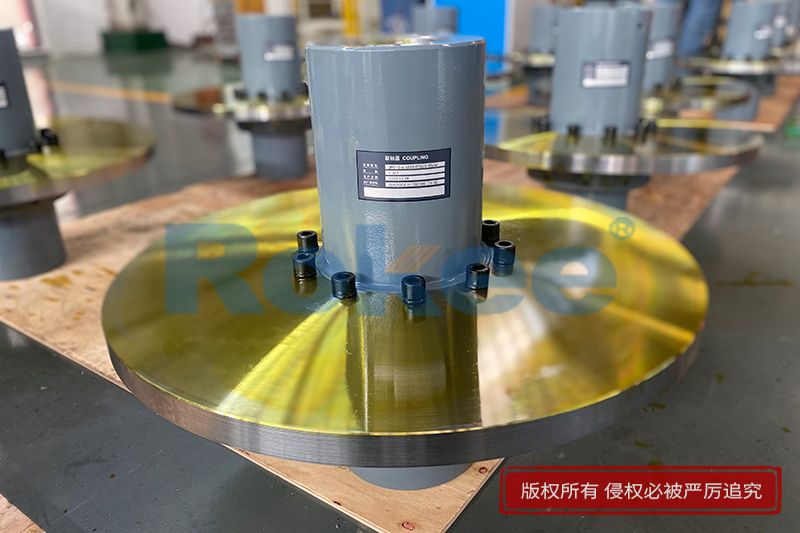

Rokee® Customized LMPK Plum Blossom Coupling With Brake Disc for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

LMPK plum coupling with brake disc is a high-performance mechanical connection device that integrates transmission and braking functions, representing the innovative development of modern coupling technology. This coupling cleverly combines the flexible transmission advantages of the plum blossom elastic coupling with the functionality of the brake disc, providing a more comprehensive solution for industrial transmission systems.

Compared with traditional couplings, the most significant feature of the LMPK series is the integration of a brake disc system based on the standard plum blossom coupling. This design not only retains the original shock absorption, buffering, and deviation compensation capabilities of the plum blossom coupling, but also adds emergency braking and position maintenance functions, greatly expanding the application scope and value of the coupling.

The LMPK brake disc plum blossom coupling consists of three main parts: two half couplings with brake discs and a plum blossom shaped elastic body in the middle. Half couplings are usually made of high-strength cast iron or alloy steel materials, and their surfaces are precision machined to ensure the flatness and wear resistance of the braking surface. The middle elastic body is made of high-quality polyurethane or rubber material, which has good fatigue resistance and oil resistance.

The braking system is the core innovation point of LMPK coupling. When braking is required, the external brake caliper will clamp the brake disc on the coupling, achieving rapid stopping of the shaft through friction. This built-in brake design has the advantages of fast response speed, compact structure, and small installation space compared to external brakes. Meanwhile, the plum blossom shaped elastic material can effectively absorb impact energy during braking, protecting the transmission system from sudden braking damage.

Performance Characteristics

Precise braking control: The brake disc is directly integrated into the coupling, with short braking response time and high position control accuracy, making it particularly suitable for automation equipment that requires precise positioning.

Excellent deviation compensation capability: Plum shaped elastomers can effectively compensate for axial, radial, and angular deviations, generally achieving compensation amounts of ± 0.5mm in the axial direction, ± 0.2mm in the radial direction, and ± 1 ° in the angular direction.

Shock absorption and noise reduction: Elastic components can absorb vibrations and impacts during the transmission process, reduce noise, and extend the service life of equipment.

Maintenance free design: High quality materials and precision manufacturing processes ensure that the coupling does not require lubrication under normal working conditions, resulting in low maintenance costs.

Compact structure: Integrated design saves installation space, especially suitable for modern equipment layouts with limited space.

LMPK with brake disc plum blossom coupling has been widely used in multiple industrial fields due to its unique advantages:

Automated production line: used for automated equipment such as robotic arms and assembly robots that require precise positioning

CNC machine tools: applied to spindle transmission systems to achieve rapid braking and position maintenance

Lifting equipment: providing reliable braking safety guarantee for cranes and elevators

Packaging Machinery: Achieving Precise Shutdown and Position Control on High Speed Packaging Lines

New energy equipment: wind turbine yaw system, solar tracking system, etc

Choosing the appropriate LMPK coupling requires consideration of multiple factors:

Torque parameters: Select the appropriate model based on the maximum working torque and braking torque requirements of the transmission system

Speed range: Ensure that the rated speed of the coupling is higher than the maximum operating speed of the system

Environmental conditions: Consider factors such as temperature, humidity, corrosiveness, etc. to select corresponding materials and protection levels

Deviation situation: Evaluate the degree of axis alignment deviation to ensure it is within the range of coupling compensation capability

Special attention should be paid during installation:

Ensure that the tolerance fit between the shaft and the coupling hole is appropriate

Tighten the bolts evenly according to the specified torque value

The gap adjustment between the brake disc and brake caliper should meet the technical requirements

Avoid forced installation that may cause deformation or damage to the elastic body

Although LMPK couplings are designed as maintenance free, regular inspections are still necessary

Regular inspection: Check the elastomer for cracks, hardening, or permanent deformation every 3-6 months

Brake system monitoring: Pay attention to the wear of the brake disc to ensure that the brake surface is clean and free of oil stains

Abnormal vibration analysis: If abnormal vibration is found, the alignment of the coupling and the state of the elastic body should be checked immediately

Temperature monitoring: Overheating during braking may affect performance, and it is necessary to ensure good heat dissipation conditions

Common faults and troubleshooting methods:

Decreased braking effect: Check the wear of the brake disc and replace it if necessary; Clean the brake surface

Abnormal noise: Check if the elastic body is damaged and if the shaft alignment is good

Coupling overheating: Check for overloaded operation and complete release of brakes

LMPK plum blossom coupling as an upgraded product of traditional plum blossom coupling, provides a more complete transmission solution for modern industrial equipment through innovative brake integration design. Its excellent performance and wide applicability make it play an irreplaceable role in industrial environments with increasing automation. With the continuous advancement of technology, this type of coupling will continue to evolve, bringing more possibilities to the industrial transmission field.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/lmpk-plum-blossom-coupling-with-brake-disc.html