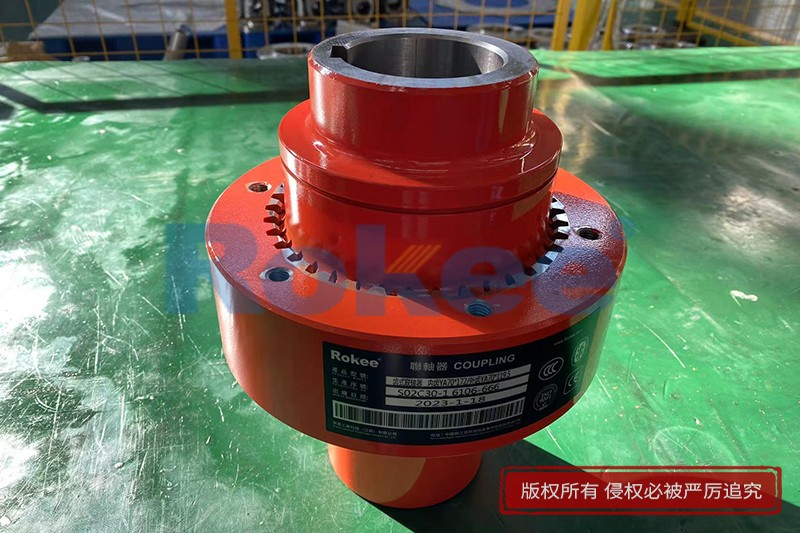

Rokee® Customized Internal and External Gear Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

As a key component in modern industrial transmission systems, internal and external gear couplings play an irreplaceable role in the fields of heavy machinery and precision equipment. This type of coupling, through its unique gear meshing design, can not only efficiently transmit torque, but also effectively compensate for installation deviations in the axial, radial, and angular directions, thereby significantly improving the stability and service life of the transmission system.

The internal and external gear coupling belongs to a type of rigid movable coupling, and its core design concept is to achieve shaft connection through gear meshing while allowing a certain degree of relative displacement. This type of coupling is mainly composed of an outer gear shaft sleeve and an inner gear ring, which transmits torque through the meshing of gears, and compensates for shaft system deviation using tooth flank clearance and tooth profile design.

The basic structure includes:

External gear sleeve: a half coupling with external gears, usually made of high-strength alloy steel

Internal gear ring: an annular component with an internal gear that meshes with an external gear sleeve

Sealing device: prevents lubricant leakage and blocks external pollutants from entering

Connecting bolt: used to fix the coupling at the shaft end

Lubrication system: including oil holes, oil passages, and grease/oil chambers, etc

The working principle is to transmit torque through gear meshing. When the driving shaft rotates, the torque is transmitted to the driven shaft through the meshing of the outer gear sleeve and the inner gear ring. When there is relative displacement between the two axes, the special design of the gear allows for relative sliding between the tooth surfaces, thereby compensating for axis deviation without generating excessive additional loads.

The excellence of the internal and external gear coupling lies in its carefully designed structural features, which work together to make it perform well in various working conditions.

Gear design features

Drum shaped tooth design: The advanced external teeth adopt a spherical drum shaped design, with the spherical center located on the gear axis, and the tooth side clearance is larger than that of conventional gears

Tooth shape optimization: using involute tooth shape, pressure angle is usually 20 °, ensuring smooth meshing

Tooth surface treatment: The tooth surface has undergone carburizing and quenching treatment, with a hardness of HRC58-62 and strong wear resistance

Materials and Manufacturing Processes

Material selection: High quality alloy steels such as 42CrMo and 20CrMnTi are mainly used

Heat treatment process: quenching and tempering treatment+carburizing quenching to ensure the hardness of the tooth surface and the toughness of the core

Processing accuracy: The cumulative error of tooth pitch is controlled within 0.025mm, far higher than the industry standard

Lubrication and sealing system

Lubrication method:

Lubricating grease: using NLGI 2 # extreme pressure lithium based grease, suitable for medium and low speed applications

Forced oil lubrication: used for high-speed and heavy-duty applications, requiring high-precision filtrationSealing technology:

Radial labyrinth seal

Double lip oil seal

Integral sealed end cap

compensation capability

Angular compensation: ± 1 ° 30 ′

Radial compensation: 0.4-6.3mm

Axial compensation: ± 1-15mm (some models can reach ± 50mm)

The internal and external gear couplings, with their unique design, demonstrate outstanding performance in various aspects in the field of industrial transmission

Technical performance advantages

High load-bearing capacity: The torque transmission capacity can reach up to 4500kN · m level

High transmission efficiency: up to 99.7%, close to rigid couplings

Vibration and noise reduction: can reduce system vibration by 60-70% and noise by 8-12dB (A)

Long service life: The service life of high-quality products can reach three times that of straight tooth couplings

Application field

Metallurgical industry: rolling mills, continuous casting equipment, etc

Mining machinery: mine hoists, crushers, etc

Energy sector: Hydroelectric power generation units, wind power equipment

Lifting and transportation: port cranes, bridge cranes

Special environment: Corrosive environments such as ships and marine engineering

economic benefits

Reduce downtime losses

Reduce maintenance costs

Extend equipment lifespan

Significant energy-saving effect

Main model series

GICL/GIICL Series: Basic Type Internal and External Gear Couplings

GCLD series: Special type for motor shaft extension

WG series: with brake wheel design

NGCL series: heavy-duty with brake wheel type

CLZ series: Crane specific type

As a key component of industrial transmission systems, the correct selection and application of internal and external gear couplings have a profound impact on equipment reliability and production efficiency. With the advancement of technology, intelligence, miniaturization, and composite functionalization will become the future development direction, providing more efficient and reliable solutions for industrial transmission.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/internal-and-external-gear-coupling.html