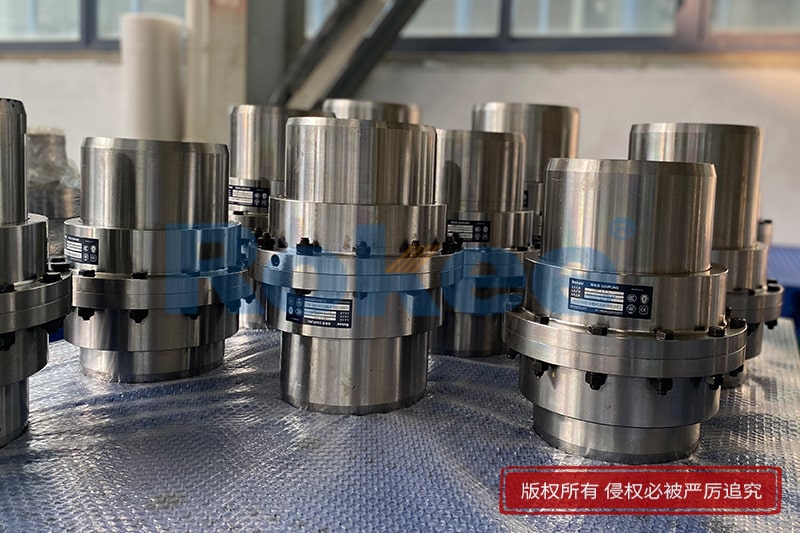

Rokee® Customized GIICL10 Curved Tooth Gear Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

GIICL curved tooth gear coupling is a rigid flexible coupling consisting of an inner ring gear and a flange half coupling with outer teeth. Its core design adopts a spherical drum shaped tooth structure, which has stronger axis deviation compensation ability and higher transmission efficiency (up to 99.7%) compared to traditional straight tooth couplings. It is widely used in metallurgy, mining, lifting and transportation, petrochemicals and other fields, and gradually expanded to high-end scenarios such as power generation and ships.

Core features and advantages

Excellent compensation capability

Angular compensation: The allowable angular displacement is 1 ° 30 ′, which is 50% higher than the straight tooth type.

Radial/axial compensation: By optimizing the contact through the drum shaped tooth surface, stress concentration is avoided and the service life is extended.Efficient transmission performance

The load-bearing capacity is increased by 15% -20% compared to the straight tooth type, with a nominal torque range of 0.4-4500kN · m, covering low-speed heavy load conditions.

The transmission efficiency is as high as 99.7%, the noise is low, and the maintenance cycle is long.Structural design optimization

Type I: Separated sealing end, allowing for larger radial displacement, suitable for Y, J1, Z1 type axial extension.

Type II: Integral sealed end, compact structure, suitable for Y and J1 type shaft extensions, with small moment of inertia.Materials and processes

High strength materials such as 45 # steel, 40Cr, and 42CrMo are used, and processed through quenching and high-frequency quenching processes to ensure wear resistance and fatigue strength.

Selection suggestion

Low speed heavy load: Priority should be given to the GICL series with wide tooth design (such as metallurgical equipment).

Compact Space: Choose the GIICL series with narrow tooth design (such as chemical pump sets).

High speed scenario: Customization of high-precision dynamic balancing models is required (such as gas turbine transmission).

Application scenarios

Metallurgical industry: Heavy equipment such as continuous casting machines and rolling mills, capable of withstanding high temperatures and loads.

Mining machinery: ball mills, crushers, suitable for dust environments and impact loads.

Lifting and transportation: Bridge crane lifting mechanism, compensating for installation errors.

In the field of energy, the gearbox connection of wind turbines requires high reliability.

Maintenance and Precautions

Lubrication seal: Regularly add lubricating grease to ensure lubrication of the tooth surface to reduce wear.

Installation alignment: The angular deviation should be controlled within 1.5 °, and the radial deviation should not exceed 0.2mm.

Fault prevention: Monitor abnormal vibrations or noise, and promptly check the wear of the tooth surface.

GIICL curved tooth gear coupling has become a key component of industrial transmission due to its structural advantages and technological maturity. Users need to match the model according to actual working conditions and pay attention to maintenance to maximize equipment lifespan. If you need non-standard customization or technical consultation, it is recommended to contact professional manufacturers for targeted solutions.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/giicl10-curved-tooth-gear-coupling.html