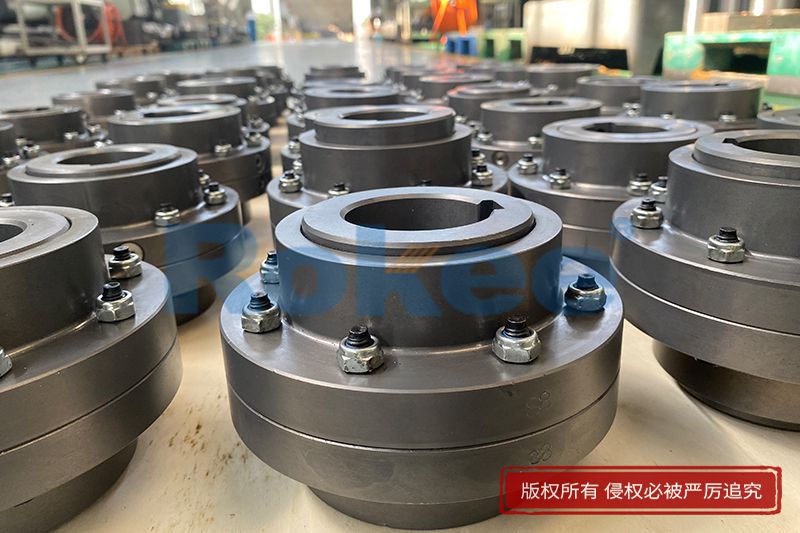

Rokee® Customized GIICL Gear Type Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

GIICL Gear Type Coupling belongs to rigid flexible coupling, mainly composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. Its core feature lies in the drum shaped design of the external teeth, where the tooth tip is spherical and the center of the spherical surface is on the gear axis. This design enables the coupling to have greater angular displacement compensation capability and better tooth surface contact conditions.

Main features of GIICL Gear Type Coupling

Strong load-bearing capacity: Compared with spur gear couplings, drum shaped gear couplings have an average load-bearing capacity increase of 15% to 20% under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling. This is due to the improved contact conditions between the inner and outer teeth on the drum shaped tooth surface, which avoids the drawbacks of stress concentration.

Large angular displacement compensation: When the radial displacement is equal to zero, the allowable angular displacement of the straight tooth coupling is relatively small, while the allowable angular displacement of the drum tooth coupling can reach 1 ° 30 ', an increase of 50%. This makes the GIICL drum toothed coupling perform well in compensating for the relative offset between the two shafts.

High transmission efficiency: The transmission efficiency of the drum shaped gear coupling is as high as 99.7%, thanks to its optimized gear design and good sealing state.

Low noise and long maintenance cycle: Due to the improved friction and wear condition of the drum shaped tooth surface, the GIICL drum shaped tooth coupling produces lower noise during operation and has a longer maintenance cycle.

Compact structure and small turning radius: GIICL Gear Type Coupling has the characteristics of compact structure and small turning radius, suitable for installation environments with limited space.

GIICL Gear Type Couplings are particularly suitable for low-speed heavy-duty working conditions, such as metallurgy, mining, lifting and transportation industries. At the same time, it is also suitable for shaft transmission of various types of machinery such as petroleum, chemical, and general machinery. Due to its greater angular compensation than spur gear couplings, drum gear couplings have been widely used both domestically and internationally.

GIICL Gear Type Coupling has a variety of models and specifications, such as G Ⅱ CL1, G Ⅱ CL2, G Ⅱ CL3, etc., to meet different transmission needs and installation environments. Users can choose appropriate models and specifications based on specific application scenarios.

To ensure the long-term stable operation of GIICL drum toothed couplings, users should regularly maintain and upkeep them. This includes checking the wear, lubrication status, and sealing performance of the coupling. For couplings equipped with forced thin oil lubrication systems or segmented grease lubrication structures, users should also regularly replace lubricating oil or grease to ensure sufficient lubrication of the tooth surface and reduce wear.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/giicl-gear-type-coupling.html