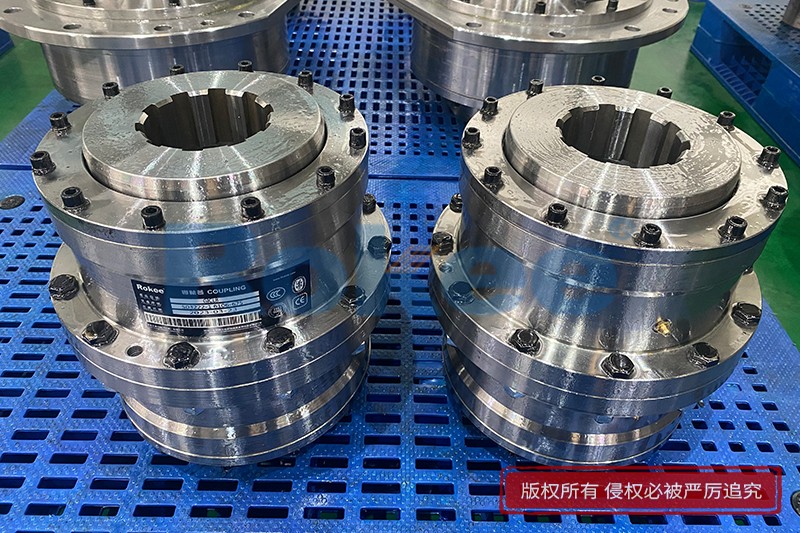

Rokee® Customized GICL8 Curved-tooth Gear Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

GICL curved-tooth gear coupling is a rigid flexible coupling device consisting of an inner gear ring and a flange half coupling with outer teeth. The core innovation lies in the adoption of a spherical drum shaped design for the outer teeth:

Drum shaped tooth geometry: tooth tip curvature radius R300-R500mm, tooth side clearance 30% -50% larger than standard gears, forming a double joint flexible structure

Dynamic compensation capability: It can simultaneously compensate for deviations of ± 5mm in the axial direction, ± 3mm in the radial direction, and 1.5 ° in the angular direction, with a 50% improvement in compensation capability compared to spur gear couplings

Torque transmission: The multi tooth synchronous meshing design makes the load distribution more uniform, with 60% of the total number of teeth in contact (only 40% for straight tooth type)

Technical Advantage

Breakthrough in carrying capacity

42CrMo alloy steel+carburizing and quenching process, tooth surface hardness HRC58-62

Under the same size, the torque capacity is increased by 15-20% compared to the straight tooth type, and the maximum torque of the GICL20 type reaches 4500kN · mIntelligent lubrication system

Graphene composite lubricating coating reduces friction coefficient to 0.02

The wear of forced thin oil lubrication is only 10% of that of grease lubrication, and the maintenance cycle is extended to 8000 hoursExtreme working condition adaptation

High temperature type, temperature resistance range -50 ℃~300 ℃ (metallurgical specific)

Corrosion resistant type adopts stainless steel material+special coating, suitable for marine environmentModular design

Cone shaped shaft hole (H7 tolerance) for quick disassembly and assembly

Integrated wear indicator device, with a safety margin of 15% and automatic warningEnergy efficiency performance

Transmission efficiency of 99.7%, power loss reduced to one-third of traditional couplings

Dynamic balance level G2.5, residual unbalance<1g · mm/kg

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/gicl8-curved-tooth-gear-coupling.html