Rokee® Customized Gear Coupling With Intermediate Pipe for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

A gear coupling with intermediate pipe is a special type of toothed coupling that adds an intermediate tube structure to the traditional toothed coupling to meet more complex transmission requirements.

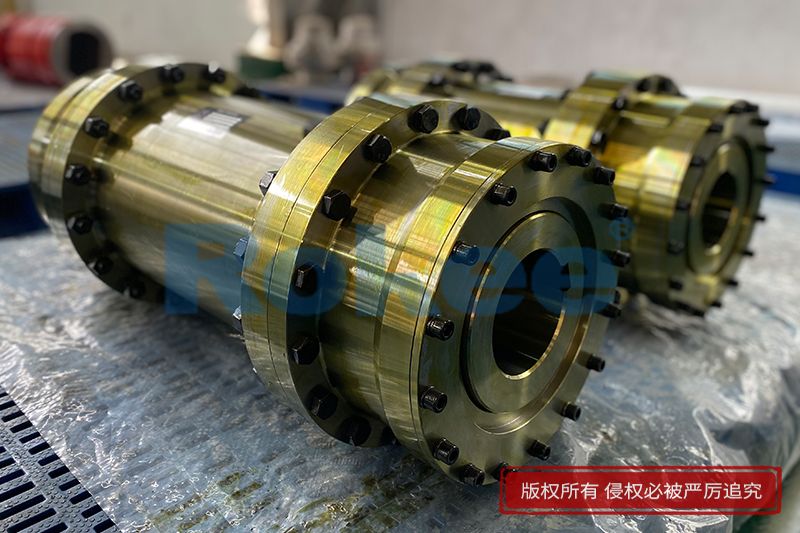

The toothed coupling with an intermediate tube mainly consists of an inner ring gear, a flange half coupling with outer teeth, an intermediate tube, and connecting bolts. Among them, the middle pipe serves as a key component connecting the two half couplings, and its material and strength need to meet the requirements of the transmission system. External teeth are divided into two types: straight teeth and drum teeth. Drum teeth couplings allow for larger angular displacement, improve tooth contact conditions, and enhance the ability to transmit torque.

The working principle of a toothed coupling with an intermediate tube is similar to that of a regular toothed coupling, both utilizing the meshing of internal and external teeth to achieve the transmission of torque and rotational motion. When the driving shaft rotates, torque is transmitted to the driven shaft through tooth contact and friction, thereby achieving synchronous rotation of the two shafts. The presence of the intermediate pipe enables the coupling to better adapt to the relative displacement between the two shafts, including axial displacement, radial displacement, and angular displacement.

Performance advantages

Strong load-bearing capacity: The toothed coupling with intermediate pipe has a large load-bearing capacity and is suitable for shaft transmission under heavy load conditions.

Strong adaptability: Due to the presence of the intermediate pipe, the coupling can better adapt to the relative displacement between the two shafts, reducing the vibration and noise caused by displacement.

Compact structure: Although an intermediate pipe structure has been added, the overall design remains compact, making it easy to install and maintain.

Long service life: Working under good lubrication and sealing conditions, with minimal tooth wear and a long service life.

Gear couplings with intermediate tubes are widely used in various shaft transmission systems that require high power transmission and relative displacement, such as metallurgy, mining, lifting and transportation, petroleum, and shipbuilding industries. Especially in transmission systems that require connecting two different axes, gear couplings with intermediate pipes can play a greater role.

When installing a toothed coupling with intermediate pipe, the following points should be noted:

Ensure specification matching: The specifications and models of the selected coupling should match the equipment requirements, and check if the parts are complete.

Clean the surface: Thoroughly clean the surfaces of the coupling and the connected shaft to remove impurities such as oil stains and rust.

Correct installation: Install the half coupling, intermediate pipe, and connecting bolts correctly according to the installation guide to ensure installation accuracy and stability.

Regular inspection and maintenance: During use, the operation status of the coupling should be regularly checked, including tooth wear, bolt tightening, etc., and maintenance and replacement should be carried out in a timely manner.

The gear coupling with intermediate pipe plays an important role in mechanical transmission systems due to its unique structure and performance advantages. In the selection and use process, its characteristics and requirements should be fully considered to ensure the normal operation and long-term stability of the equipment.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/gear-coupling-with-intermediate-pipe.html