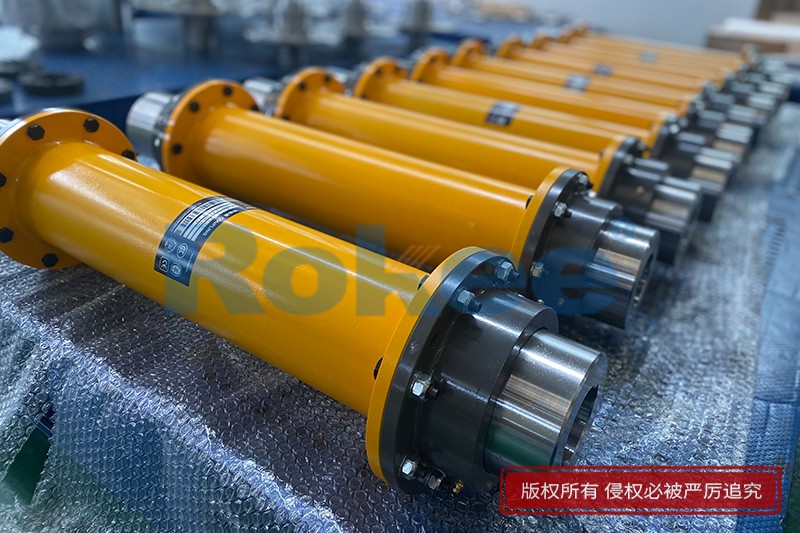

Rokee® Customized Drum Gear Coupling With Intermediate Shaft for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The drum toothed coupling with intermediate shaft is a derivative model of the standard drum toothed coupling, which adds an intermediate connecting shaft and achieves long-distance transmission and complex deviation compensation through a three-stage structure.

Technical Characteristics

Modular design

Composed of two external half couplings, a middle shaft sleeve, and an inner gear ring, the length of the shaft sleeve can be customized as needed (commonly 500-3000mm), with a maximum compensation angular displacement of 1.5 °± 0.2 °

The typical model WGJ/WGT series is forged from 42CrMo alloy steel, with a tooth surface carburizing and quenching hardness of HRC58-62, and a fatigue life of over 10 ^ 7 cyclesDynamic compensation mechanism

The intermediate shaft design can absorb axial displacement of ± 15mm (200% higher than ordinary drum gear couplings), suitable for mining and metallurgical equipment with foundation settlement

The double drum shaped tooth structure forms a "double joint" effect, with angular compensation capability added up to 3 °, while reducing single-sided tooth surface contact stress by 40%

Long distance transmission solution

The intermediate shaft is designed with hollow forgings (wall thickness ≥ 20mm), which reduces weight by 35% compared to solid shafts while maintaining a torque capacity of 90%

Special centering structures (such as conical positioning sleeves) ensure installation accuracy of ≤ 0.05mm/m, avoiding long axis vibration

Extreme working condition adaptation

High temperature type: The intermediate shaft is equipped with heat dissipation fins, and the temperature resistance range is extended to -50 ℃~300 ℃ (for metallurgical rolling mills)

Corrosion resistant type: stainless steel intermediate shaft+special lubricating grease, suitable for salt spray environments such as offshore platforms

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/drum-gear-coupling-with-intermediate-shaft.html