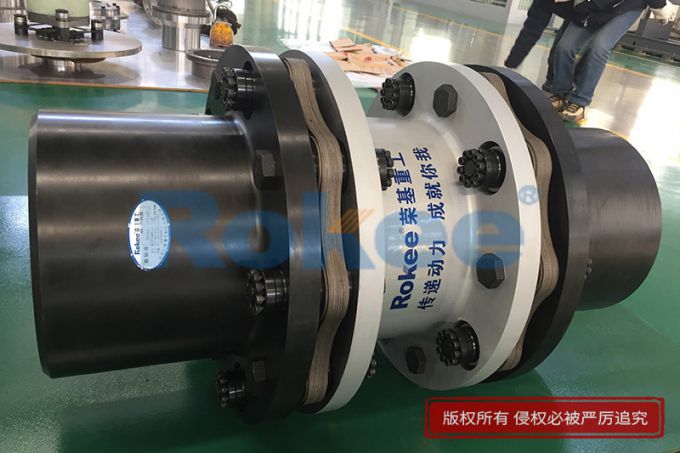

Rokee® Customized Diaphragm Couplings For Steam Turbines for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The diaphragm coupling used in steam turbines is a high-performance metal strong element flexible coupling that plays a key role in steam turbine systems.

The steam turbine diaphragm coupling is mainly composed of two half couplings, an intermediate sleeve, and a flexible element composed of several stainless steel sheets. These stainless steel sheets are key components of the diaphragm coupling, which are connected to the two halves of the coupling through staggered bolts to form a flexible connection. The membrane coupling has a compact structure, high strength, long service life, and does not require lubrication.

The working principle of the steam turbine diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two shafts connected. When there is axial, radial, or angular deviation between the two shafts, the diaphragm will undergo elastic deformation to absorb these deviations and ensure smooth transmission between the two shafts. At the same time, the diaphragm coupling can also provide good angular compensation and buffering effect.

In the process of torque transmission, torque is input from the active end half coupling, transmitted to the front end flexible steel plate group through high-strength bolts, and then transmitted to the middle sleeve through high-strength bolts by the flexible steel plate group. It is also output by the rear end flexible steel plate group, high-strength bolts, and driven half coupling. This completes the transmission of torque and achieves energy transfer.

Diaphragm couplings are suitable for high-speed and high-power steam turbines, such as aviation derived gas turbines. Its non lubrication characteristic makes it perform well in shaft transmission under high temperature, high speed, and corrosive medium working conditions. In addition, membrane couplings can withstand various acid and alkali corrosion in actual production, and have a wide range of application prospects.

Advantages and Characteristics

High performance: The turbine diaphragm coupling has high strength, rigidity, and durability, and can withstand large torque and axial and radial loads.

No lubrication required: The turbine diaphragm coupling does not require lubrication during operation, reducing maintenance costs and environmental pollution.

Strong compensation capability: The turbine diaphragm coupling can compensate for significant axial, radial, and angular deviations, ensuring smooth operation of the equipment.

Corrosion resistance: The turbine diaphragm coupling can withstand various acid and alkali corrosion and is suitable for harsh working conditions.

Diaphragm couplings for steam turbines are a high-performance, lubrication free, highly compensated, and corrosion-resistant type of coupling. It plays a crucial role in the steam turbine system, ensuring the smooth operation and efficient transmission of equipment.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/diaphragm-couplings-for-steam-turbines.html