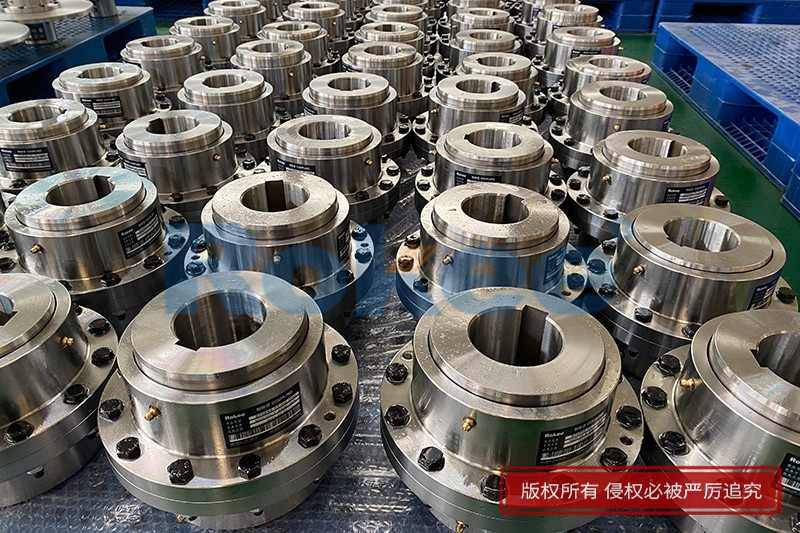

Rokee® Customized Crown Gear Couplings Exported To Mexico for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

As a key component in the field of modern mechanical transmission, crown gear couplings play an irreplaceable role in heavy industrial equipment with their unique structural design and excellent performance. This type of coupling not only solves the limitations of traditional spur gear couplings through innovative drum shaped tooth contact design, but also significantly improves the reliability and efficiency of the transmission system.

crown gear coupling belongs to the category of rigid flexible coupling, consisting of two core components: an inner gear ring and a flange half coupling with outer teeth. The unique feature of this coupling lies in its external tooth design - unlike traditional straight teeth, the external teeth of the drum shaped coupling adopt a spherical drum structure, with the spherical center located on the gear axis. This design significantly increases the tooth clearance compared to ordinary gears, giving the coupling a special performance advantage.

From the perspective of working principle, the crown gear coupling transmits torque and rotational motion through the meshing of inner and outer teeth. When there is relative displacement between the two axes, the special geometric shape of the drum teeth can adaptively adjust the contact position to avoid stress concentration. Specifically, the drum shaped tooth surface significantly improves the contact conditions between the inner and outer teeth, eliminating the problem of tooth end edge compression in straight tooth couplings under angular displacement conditions. During operation, even if there are axial, radial, or angular deviations, the drum shaped tooth surface can maintain uniform contact, converting local stress concentration into more evenly distributed contact stress.

From the perspective of material selection, high-quality crown gear couplings are usually made of 42CrMo alloy steel, and after quenching and tempering treatment, the tooth surface hardness can reach HRC58-62. This material selection can increase the lifespan of the coupling by about three times compared to ordinary 45 # steel. More advanced manufacturers will use a unique drum shaped tooth surface carburizing and quenching process to achieve a depth of 1.2-1.8mm for the wear-resistant layer on the tooth surface, far exceeding the industry average of 0.8mm, thereby further extending the product's service life.

In terms of precision control, the cumulative error of the tooth pitch of high-quality crown gear couplings can be controlled within 0.025mm, which is twice as high as the 0.05mm precision required by the national standard GB/T 3852. This high-precision manufacturing ensures uniform distribution of load on the tooth surface and is also one of the key factors for the coupling to achieve a transmission efficiency of up to 99.7%.

Compared with traditional spur gear couplings, drum gear couplings exhibit a series of significant technological advantages, which have rapidly replaced spur gear products in the heavy industry sector. From the perspective of bearing capacity, under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the bearing capacity of the crown gear coupling is on average 15% to 20% higher than that of the spur gear coupling. This improvement is due to the optimization of load distribution by the drum shaped teeth, which allows more teeth to participate in the load bearing at the same time, rather than only a few teeth bearing the main load.

Compensation capability is another prominent advantage of drum gear couplings. When the radial displacement is zero, the allowable angular displacement of a spur gear coupling is usually only 1 °, while a drum gear coupling can reach 1 ° 30 ', increasing the compensation capacity by 50%. In practical applications, this means that the crown gear coupling can better adapt to shaft installation errors and deformations during operation, providing the system with greater tolerance for deviations. This characteristic is particularly important in large equipment such as metallurgical rolling mills and mining machinery, as the base settlement and shaft deformation of these devices are often difficult to completely avoid.

The crown gear coupling also has the following significant characteristics:

Low vibration noise: The drum shaped tooth surface makes the meshing process of the inner and outer teeth smoother, reducing impact and vibration, and the noise level is significantly lower than that of the spur gear coupling

Long maintenance cycle: Optimized tooth contact conditions significantly reduce wear rate, extending maintenance intervals several times

Easy to assemble and disassemble: The outer gear sleeve has a trumpet shaped tooth end, making the assembly and disassembly of the inner and outer teeth more convenient

High space efficiency: Compact structure, with a smaller turning radius than spur gear couplings under the same torque capacity, suitable for applications with limited space

The functional expansion type includes various special designs to meet specific operating conditions:

WGP type with brake disc: Integrated brake disc function, suitable for equipment that requires quick braking

Vertical installation type (WGC type): specially designed for vertical shaft transmission, solving lubrication and sealing problems

Intermediate sleeve type (WGT type): increases axial adjustment capability for easy installation and debugging

Nylon internal gear ring type (TGL type): vibration and noise reduction, suitable for occasions with certain buffering requirements

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/crown-gear-couplings-exported-to-mexico.html