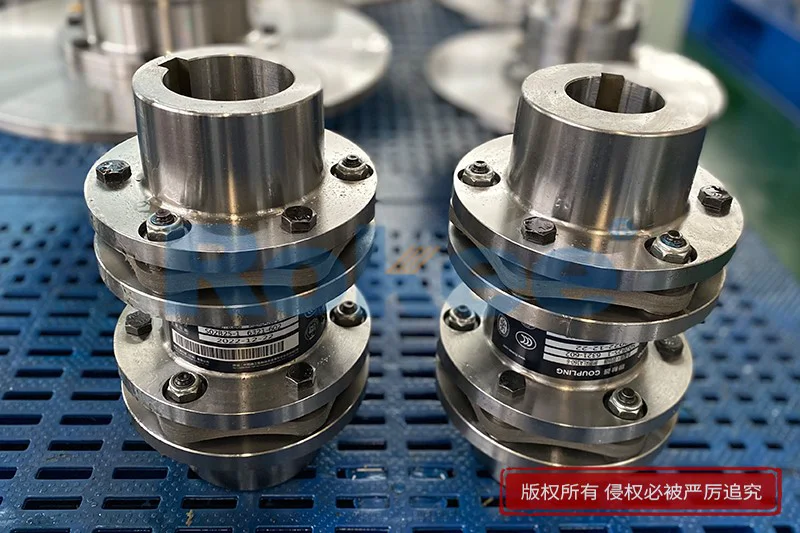

Pump diaphragm coupling is a type of coupling specifically designed for rotating mechanical equipment such as pumps. It mainly relies on the elastic deformation of the diaphragm to compensate for the relative displacement between the two shafts.

The pump diaphragm coupling is usually composed of several sets of stainless steel thin plates connected in a staggered manner to the two halves of the coupling, with each set of diaphragms consisting of several stacked pieces. This design gives the diaphragm coupling high-performance metal elastic element characteristics. The diaphragm itself is very thin, and when relative displacement loads are generated, the diaphragm is prone to bending, so it can withstand a certain deviation and generate lower bearing loads in the servo system.

Main characteristics

Strong compensation capability: The pump diaphragm coupling can compensate for axial, radial, and angular offsets caused by manufacturing errors, installation errors, load deformation, and temperature rise changes between the active and driven machines. Compared with gear couplings, its angular displacement can be doubled, the reaction force is smaller during radial displacement, and the flexibility is greater.

Shock absorption and noise reduction: It has obvious shock absorption effect, no noise, no wear, and is suitable for occasions with strict requirements for vibration and noise.

Wide adaptability: Suitable for working in high temperatures and harsh environments, and able to operate safely under conditions of impact and vibration. At the same time, it has the characteristics of acid resistance, alkali resistance, and corrosion resistance, and is suitable for shaft transmission in high-temperature, high-speed, and corrosive medium working conditions.

High transmission efficiency: High transmission efficiency, especially suitable for medium and high-speed high-power transmission.

Simple structure: lightweight, small size, easy to assemble and disassemble. It can be assembled and disassembled without moving the machine (referring to the type with intermediate shaft), does not require lubrication, and has low maintenance costs.

Accurate transmission of rotational speed: It can accurately transmit rotational speed, operate without slip, and can be used for transmission of precision machinery.

Pump diaphragm couplings are widely used in shaft transmission of various mechanical devices, especially in pump equipment such as chemical pumps, water pumps, and other high-power, high-speed rotating mechanical equipment. In addition, it is often used in fields such as compressors, fans, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, etc.

Installation precautions:

During installation, it should be ensured that the axis deviation is within the allowable range to avoid deformation or damage to the coupling.

Products with film have edges and may cause injury. It is recommended to wear protective measures such as thick gloves during installation.

Please install protective covers and other devices around the coupling to ensure safety.

Maintenance method:

Before installation, the end faces of both shafts should be cleaned and the fit of the end face key slots should be checked.

After the installation of the coupling and normal operation for a period of time, all screws must be checked for looseness and tightened to ensure their stability.

In order to prevent micro wear of the diaphragm during high-speed operation, which may cause micro cracks and damage to the diaphragm bolt holes, solid lubricants such as molybdenum disulfide can be applied between the diaphragms or the diaphragm surface can be treated with a wear-resistant coating.

The pump diaphragm coupling plays an important role in pump equipment and other rotating machinery due to its unique structure and excellent performance. When selecting and installing, its characteristics and application scope should be fully considered to ensure the normal operation of the equipment and extend its service life.

« Pump Diaphragm Coupling » Post Date: 2023/8/4

- Elastic Diaphragm Coupling Hinge

- Schematic Diagram Of Diaphragm Coupling For Dust Removal Fan

- Elastic Diaphragm Coupling Manufacturer

- Advantages Of Elastic Diaphragm Couplings

- Standard For Toothed Corrosion-resistant Diaphragm Couplings

- Elastic Diaphragm Coupling Function

- Gearbox Diaphragm Coupling

- Elastic Diaphragm Coupling Diaphragm Material

- Centering Of Elastic Diaphragm Couplings

- Advantages Of Gear Pump Equipped With Diaphragm Coupling