Laminated Toothed Coupling is a transmission component with the advantages of simple structure, high transmission efficiency, strong compensation ability, and long service life. When selecting and using, full consideration should be given to its structural characteristics and working principles, and corresponding precautions should be followed to ensure the stability and reliability of the transmission system.

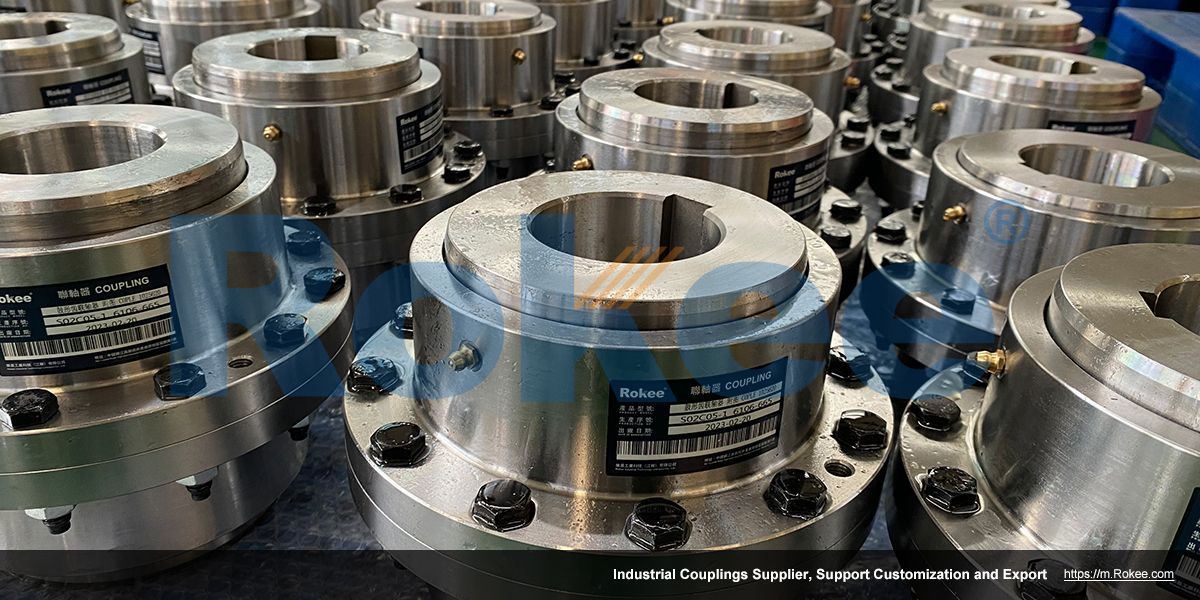

Laminated Toothed Couplings are usually composed of multiple thin metal laminations, active flanges, passive flanges, and connecting bolts. These laminations have a toothed structure that can mesh with each other to transmit torque. At the same time, the connection between the laminations and between the laminations and the flange is made by bolts or other fasteners to ensure the overall stability and reliability of the coupling.

The working principle of the laminated toothed coupling mainly relies on the elastic deformation of the laminations to compensate for the angular and axial displacement between the shafts. When there is relative motion between the two axes, the laminations undergo elastic deformation, thereby absorbing and transmitting torque. At the same time, the tooth shaped structure can increase the meshing area and friction force, improve the transmission efficiency and load-bearing capacity of the coupling.

Advantage

Simple structure: The structure of the laminated toothed coupling is relatively simple, easy to manufacture and install.

High transmission efficiency: Due to the presence of the toothed structure, the coupling can more effectively transmit torque and reduce energy loss.

Strong compensation capability: The laminated structure has a certain degree of elastic deformation ability, which can compensate for angular and axial displacements between shafts, improving the stability and reliability of the transmission system.

Long service life: The laminated toothed coupling is made of high-quality metal materials, which have excellent wear resistance and fatigue resistance, ensuring long-term stable operation.

Laminated Toothed Couplings are widely used in various transmission systems, especially in situations where relative motion between shafts needs to be compensated. For example, in the fields of mechanical equipment, automobile manufacturing, aerospace, etc., laminated toothed couplings play an important role.

Precautions

High installation accuracy requirements: The laminated toothed coupling needs to ensure precise fit between various components during installation to avoid transmission problems caused by installation errors.

Regular inspection and maintenance: In order to ensure the long-term stable operation of the laminated toothed coupling, it is necessary to regularly inspect and maintain it, including checking the wear of the laminations and the looseness of fasteners.

Avoid overload use: When using laminated toothed couplings, overload use should be avoided to prevent laminated breakage or transmission failure due to excessive torque.

« Laminated Toothed Coupling » Post Date: 2023/9/19

URL: https://m.rokee.com/blog/laminated-toothed-coupling.html

- Abnormal Sound From Drum Gear Coupling

- Floating Gear Coupling

- Flange Toothed Coupling

- Service Life Of Drum Gear Coupling

- Forged Steel Toothed Coupling

- High Elastic Toothed Water Pump Coupling

- Shaft End Dimensions Of Drum Gear Coupling

- High Speed Toothed Coupling

- Motor Drum Type Toothed Coupling

- Shape Of Drum Gear Coupling