Rokee® Customized Shim Pack Coupling For Steam Turbine for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

As a key component of the steam turbine transmission system, the shim pack coupling plays an irreplaceable role in power transmission and shaft connection.

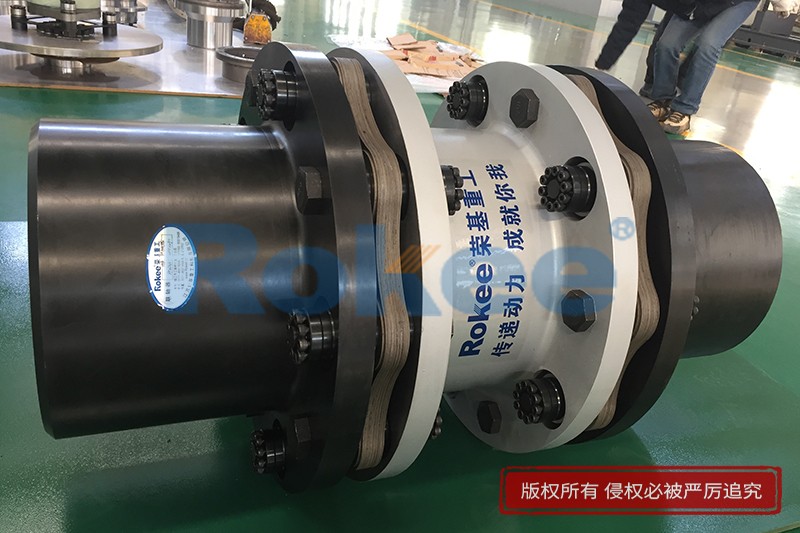

The shim pack coupling for steam turbines mainly consists of the following parts:

Metal diaphragm group: made of multiple sets of high-strength stainless steel thin plates stacked together, divided into two forms: connecting rod type or integral type, and is the core elastic element of the coupling

Shaft sleeve: a key component connecting the rotor of a steam turbine and the rotor of a generator, usually made of high-strength alloy steel

High strength connecting bolts: fix the diaphragm and shaft sleeve to form a complete transmission structure, and the bolt material is mostly alloy steel and heat-treated

Flange: used for connecting high-power couplings, ensuring docking accuracy through precision machining

The shim pack coupling compensates for the relative displacement between the two shafts of the turbine and generator through the elastic deformation of the metal diaphragm. When the driving shaft (turbine rotor) rotates, torque is transmitted to the diaphragm through the bolt group, and then transmitted to the driven shaft (generator rotor) through the diaphragm. The diaphragm can generate controllable elastic deformation while bearing torque, allowing for a certain installation deviation between the two shafts.

During the operation of the steam turbine, the shim pack coupling needs to compensate for three main deviations:

Axial displacement: Axial expansion and contraction caused by thermal expansion, usually up to ± 5mm

Radial deviation: center offset caused by installation error or bearing wear, generally allowed to be 0.5-1mm

Angular deviation: The angular deviation caused by the non parallel centerline of two axes, with a permissible range of 0.5 ° -1.5 °

The operating conditions of steam turbines impose extremely high requirements on transmission components, and shim pack couplings demonstrate significant advantages in this field:

Non lubrication design: completely eliminates the need for lubrication and avoids contamination of the turbine system by lubricant leakage

High temperature resistance: Made of special alloy material, it can work stably in an environment of -80 ℃ to+300 ℃ for a long time

High compensation capability: can simultaneously compensate for axial, radial, and angular deviations, adapting to deformation during hot operation of the steam turbine

Vibration suppression: The multi-layer stainless steel diaphragm group can effectively attenuate 30% -40% of torsional vibration, protecting the bearing system

Ultra high transmission efficiency: The direct metal to metal connection method achieves a transmission efficiency of up to 99.86%

Maintenance free and long-lasting: The structure is simple and reliable, with a design lifespan typically exceeding 100000 hours

Precise transmission: no rotational clearance, able to accurately transmit speed, ensuring stable power generation frequency

When selecting a shim pack coupling for a steam turbine, the following key parameters need to be considered comprehensively:

Torque capacity: Calculate the maximum torque based on the rated power and speed of the steam turbine, taking into account the instantaneous overload capacity

Speed range: It must meet the working speed requirements of the steam turbine, including overspeed test conditions (usually 110% -120% of the rated speed)

Thermal expansion compensation: Evaluate the axial expansion of the steam turbine from cold to hot state and select appropriate compensation capability

Critical speed: The coupling design must ensure that the operating speed is far from the critical speed range of the system

Shaft hole size: matching the diameter of the turbine and generator shafts, the shaft hole of large units is usually 150-400mm

Environmental adaptability: Consider the corrosion issues that may arise from steam environments

Shim pack couplings have become a standard configuration for modern steam turbine transmissions due to their excellent performance and reliability. Proper selection, precise installation, and scientific maintenance will ensure its long-term stable operation in steam turbine generator units, providing efficient and reliable power transmission guarantees for electricity production. With the advancement of technology, the future of steam turbine shim pack couplings will continue to develop towards a more intelligent and reliable direction.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/shim-pack-coupling-for-steam-turbine.html