The code of drum gear coupling is an important basis for the selection and application of couplings, and its analysis and application are crucial for ensuring equipment performance. By gaining a deeper understanding of the code structure and meaning of drum shaped gear couplings, we can more accurately select the appropriate coupling type, size specifications, and design features to meet the needs of different application scenarios.

The code for a drum toothed coupling is usually composed of a series of letters and numbers, which not only represent the basic type and size specifications of the coupling, but also contain its specific design features and performance parameters. For example, a typical drum toothed coupling code may include prefixes indicating the coupling type (such as "GJ" representing drum toothed), numbers indicating the shaft hole diameter, numbers indicating the shaft hole length, and suffixes indicating other special design requirements.

Code analysis of drum gear coupling

Type prefix: The type prefix of drum toothed couplings is usually used to distinguish between different types of couplings. For example, "GJ" may represent a specific series of drum toothed couplings. Different manufacturers or standards may use different prefixes, so it is necessary to refer to specific product manuals or standards in practical applications.

Size specifications: The size specification section usually includes two key parameters: shaft hole diameter and shaft hole length. The diameter of the shaft hole is used to ensure that the coupling can be tightly installed on the shaft, while the length of the shaft hole determines the connection strength between the coupling and the shaft. These parameters are typically represented in numerical form and follow specific naming conventions.

Design features: The design features section may include information such as the inclination angle, number of teeth, and material selection of the drum shaped teeth. These pieces of information are crucial for understanding the performance characteristics of the coupling. For example, the inclination angle of the drum shaped teeth can affect the compensation ability of the coupling, while the number of teeth and material selection directly affect the bearing capacity and service life of the coupling.

Suffix: The suffix part is usually used to indicate special design requirements or additional functions of the coupling. For example, some drum toothed couplings may be equipped with lubrication or heating devices to meet specific application requirements. These special requirements are usually represented in the suffix of the code in the form of a combination of letters or numbers.

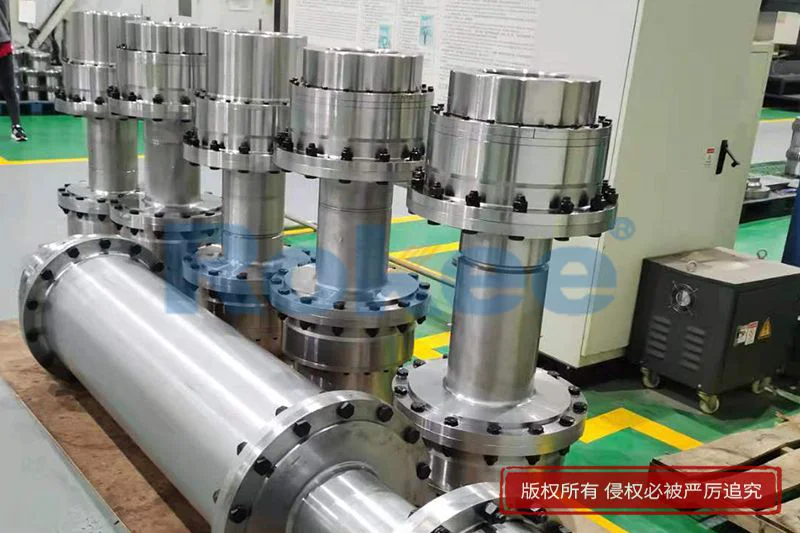

Crown gear couplings are widely used in various industrial fields, especially in situations where shaft deviation compensation, vibration reduction, and noise reduction are required. For example, in industries such as paper machinery, textile machinery, and food processing machinery, drum tooth couplings can effectively transmit torque and absorb shaft system deviations, thereby improving equipment stability and reliability. In addition, in the fields of heavy machinery such as ships and wind power generation, drum gear couplings are also favored due to their strong load-bearing capacity and good compensation performance.

« Drum Gear Coupling Code » Post Date: 2023/8/28

- Drum Gear Coupling Balance

- Which Is Cheaper For Drum Gear Couplings

- Drum Gear Coupling Baffle

- Drawing Method For External Teeth Of Drum Gear Coupling

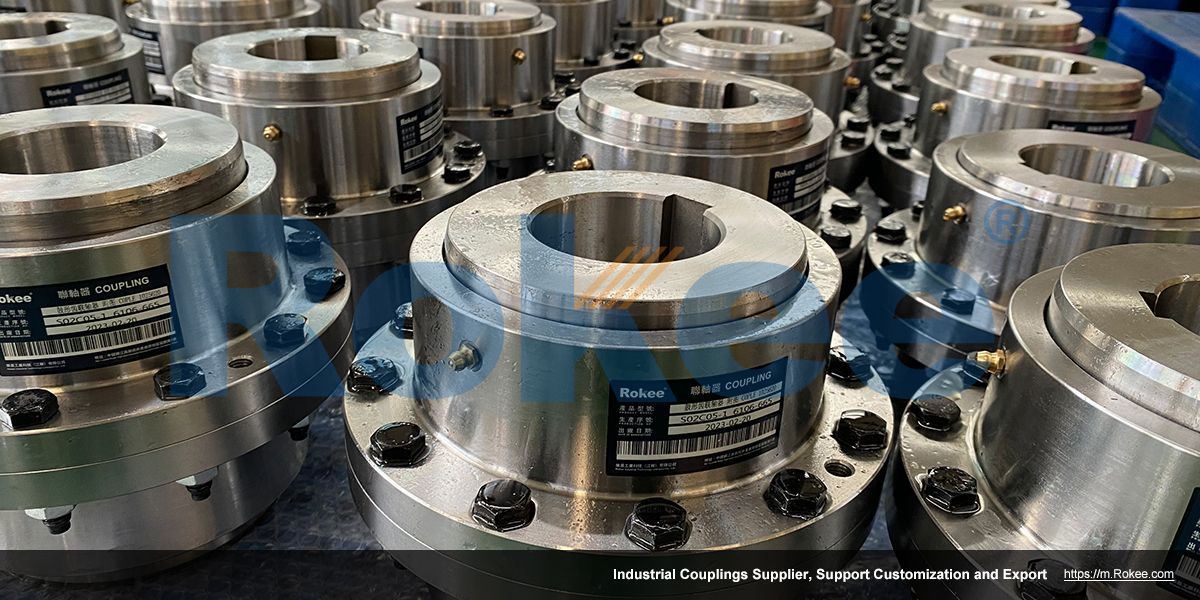

- Production And Supply Of Drum Gear Couplings

- Drawing Method Of Drum Gear Coupling

- Does The Drum Gear Coupling Housing Rotate

- High Quality Merchants Of Drum Gear Couplings

- Do Drum Gear Couplings Require Oil Filling

- Do Drum Gear Couplings Require Lubrication