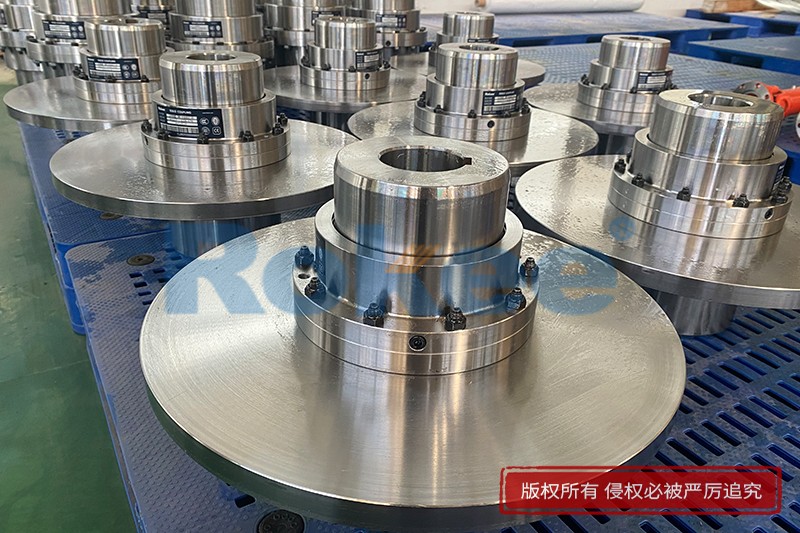

Rokee® Customized Crown Gear Coupling With Brake Disc for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The crown gear coupling with brake disc consists of three main parts:

Drum shaped gear transmission unit

Adopting an internal gear ring and external gear flange half coupling meshing structure, the external teeth are designed as spherical drum shaped teeth (the curvature radius of the tooth top is usually 3-5 times the tooth width), with a 30% -50% increase in tooth side clearance compared to a straight tooth coupling, allowing angular displacement of 1.5 ° -2 °, axial displacement of ± 2mm, and radial displacement of ± 0.5mm.Integrated brake disc module

The diameter range of the brake disc is 315-1000mm (such as WGP type), forged from high-strength cast iron or alloy steel, with a surface hardness of HRC45-55 and a friction coefficient of ≥ 0.35. It can be directly matched with hydraulic caliper disc brakes or electromagnetic brakes.Lubrication and sealing system

Standard lithium grease lubrication or forced thin oil lubrication, with wear only 10% of grease lubrication during thin oil lubrication, and integrated labyrinth seal+fluororubber oil seal dual protection.

Core advantages:

Composite compensation capability: It can still compensate for a radial deviation of 0.5mm under braking conditions, avoiding system jamming caused by axial thrust generated during braking.

Dynamic balance design: The brake disc undergoes G2.5 dynamic balance treatment, with a residual unbalance of ≤ 1g · cm/kg, ensuring high-speed braking stability.

Thermal management optimization: The design of the brake disc cooling ribs ensures that the surface temperature rise is ≤ 120 ℃ (continuous braking conditions), avoiding thermal deformation that affects tooth contact.

Application scenarios

Metallurgical rolling mill

In the hot rolling production line, a hydraulic braking system is used to achieve rapid braking of the rolling mill rolls and compensate for axial displacement caused by roll movement.Port crane

The lifting mechanism adopts WGZ type coupling, and the brake disc is matched with the normally closed brake.Mine crusher

Adapting to impact loads, the brake disc is designed to withstand dust, and the lubrication system is equipped with a magnetic oil filter device.

The crown gear coupling with brake disc maintains excellent deviation compensation capability even under heavy load emergency braking conditions through integrated design of braking and transmission. It is the core transmission component of key equipment such as metallurgy and lifting.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/crown-gear-coupling-with-brake-disc.html