Rokee® Customized JS Serpentine Spring Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

JS serpentine spring coupling is an advanced metal elastic coupling widely used in the field of heavy machinery due to its unique structural design and excellent performance characteristics.

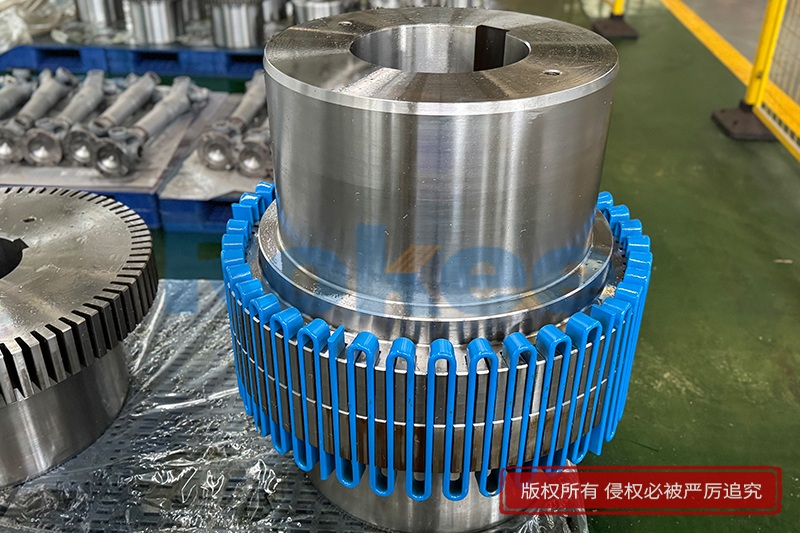

JS snake shaped spring coupling belongs to a type of metal elastic coupling, which achieves power transmission through snake shaped spring plates embedded in the tooth grooves of the two halves of the coupling in the axial direction. This design makes it one of the most advanced shaft connected transmission components in the international mechanical field today.

Working principle: When the coupling is in operation, it relies on the axial force exerted by the active end teeth on the serpentine spring to drive the driven end to transmit torque. The contact point between the spring and the tooth profile will change with the magnitude of the torque, forming an increasing stiffness characteristic, making this type of coupling particularly suitable for working conditions with large torque fluctuations and short shaft end distances.

Compared with traditional non-metallic elastic element couplings such as elastic sleeve pin and nylon rod pin couplings, JS serpentine spring couplings have a longer service life and higher transmission efficiency (up to 99.5%). Its short-term overload capacity can reach 2-3 times the rated torque, with a vibration reduction rate of over 36%, effectively avoiding system resonance phenomena.

The core structure of JS serpentine spring coupling includes two half couplings, two half housings, two sealing rings, and snake shaped spring plates. According to different tooth designs, it can be divided into two types: constant stiffness and variable stiffness:

Linear tooth profile: Under normal load, the distance between the snake spring and the tooth contact point remains constant, and the stiffness is constant. It belongs to a constant stiffness coupling and is suitable for working conditions with small changes in torque transmission.

Curved tooth profile: When the load increases, the deformation of the spring increases, the distance between the contact point and the tooth decreases, and the stiffness increases. It belongs to a variable stiffness coupling and is suitable for working conditions with large torque changes and forward and reverse rotation, with better buffering effect.

The main technical advantages include:

Excellent anti vibration performance: Optimized structural design effectively avoids system resonance phenomenon, with an average vibration reduction rate of over 36%.

Strong load adaptability: It can withstand short-term overload conditions of 2-3 times the rated torque, especially suitable for impact loads.

Efficient transmission: The transmission efficiency is as high as 99.5%, far higher than that of general elastic couplings.

Easy installation and maintenance: Modular structural design, supporting quick installation and disassembly, allowing for significant radial, angular, and axial installation deviations.

Long life design: The trapezoidal cross-section snake shaped spring plate is made of high-quality spring steel through special heat treatment technology, with a long service life.

Good lubrication and noise reduction: The aluminum alloy casing not only protects the spring from swinging, but also provides good lubrication and absorbs noise with the grease filled inside.

The JS series snake shaped spring coupling includes multiple specifications and models, mainly divided into nine types:

JS shell radial installation type (basic type)

JSB shell axial installation type

JSS double flange connection type

JSD single flange connection type

SJS intermediate shaft type

JSG high-speed type

JSZ with brake wheel type

JSP with brake disc type

JSA safety type

JS serpentine spring couplings are widely used in various heavy machinery and impact equipment due to their excellent performance characteristics

Mining equipment: power system connection for crushing equipment such as coal crushers and stone crushers

Metallurgical industry: transmission systems for heavy equipment such as rolling mills and continuous casting machines

Power industry: shaft connections for generator sets, large water pumps, and other equipment

Construction machinery: transmission components of heavy machinery such as lifting equipment and excavators

Reciprocating motion mechanism: a device such as a crank connecting rod mechanism that experiences impact loads

Other industrial fields: various occasions that require connecting motors and shafts, motors and gearboxes, or shafts and shafts

The JS snake shaped spring coupling has become an indispensable key component in the field of heavy machinery transmission due to its excellent performance and reliability. Correctly selecting, installing, and maintaining couplings can significantly improve equipment operating efficiency and lifespan, and reduce maintenance costs.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/js-serpentine-spring-coupling.html