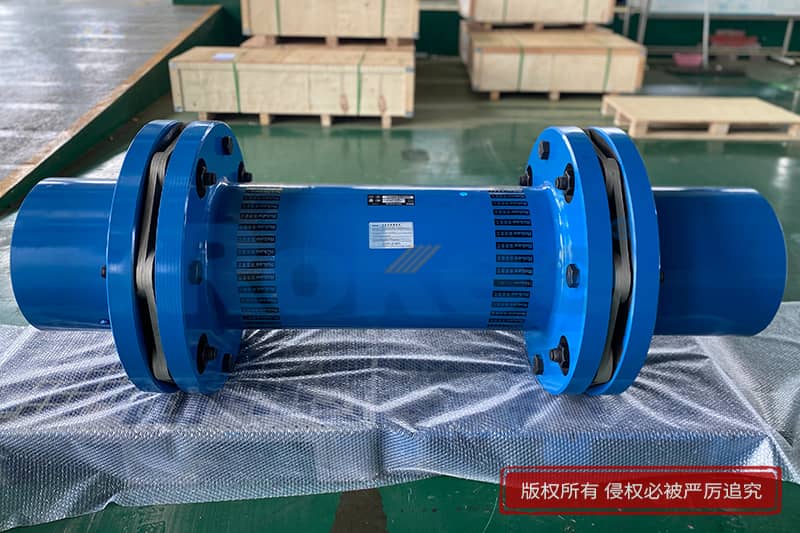

Rokee® Customized Elastic Laminated Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

Elastic laminated coupling is a special type of coupling that transmits motion and power between the teeth of two halves of the coupling through discontinuous sets of spring plates or laminated plates placed between the teeth.

Structural Characteristics

Stacked component: The core component of an elastic laminated coupling is an elastic element composed of several stainless steel sheets (or other suitable materials) stacked together. These laminations typically have a small thickness (such as 0.3mm) and are designed to undergo elastic deformation to compensate for relative displacement between axes.

Tooth to tooth transmission: For ease of processing, the teeth on the two halves of the coupling are usually separately made into cylindrical pins with tooth grooves. Each set of spring plates or laminations is embedded in the tooth slots of two cylindrical pins and fixed into individual spring components with pins. These components are then inserted into the holes of the two halves of the coupling flange to transmit torque.

Gap fit: The gap fit between the toothed cylindrical pin on the other end of the spring component and the hole on the flange allows for a certain relative displacement between the shafts, thereby enhancing the compensation performance of the coupling.

Performance Advantages

High load-bearing capacity: Due to the elastic deformation ability of laminated components, elastic laminated couplings can withstand large torques and axial and radial displacements.

Good compensation performance: The elastic deformation of laminated components can compensate for misalignment between shafts, including angular deviation, radial displacement, and axial displacement, thereby improving the stability and reliability of the transmission system.

Easy to assemble and disassemble: The structural design of the elastic laminated coupling makes it relatively easy to assemble and disassemble, making it convenient for maintenance and replacement.

Elastic laminated couplings are widely used in various mechanical equipment, especially in situations where large torque needs to be transmitted and relative displacement between compensating shafts needs to be compensated. For example, in industries such as petroleum, chemical, lifting and transportation, metallurgy, etc., elastic laminated couplings play an important role.

Precautions

Material selection: The material of the laminated component should have good elasticity and corrosion resistance to ensure the long-term stable operation of the coupling.

Lubrication and maintenance: During the use of the coupling, regular lubrication and maintenance should be carried out to reduce wear and extend its service life.

Installation precision: the installation precision of elastic laminated coupling has a great impact on its performance, so alignment adjustment shall be carried out strictly according to requirements during installation.

Elastic laminated couplings have been widely used in many fields due to their unique structure and excellent performance. When selecting and using, reasonable selection and maintenance should be made according to specific working conditions and requirements.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/elastic-laminated-coupling.html