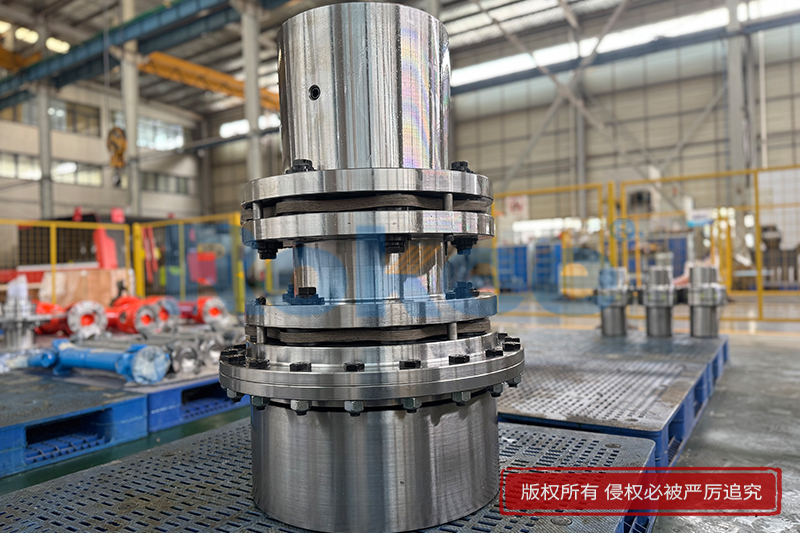

Rokee® Customized Double Diaphragm Coupling Exported To Russia for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

Double diaphragm coupling is a key mechanical connecting component in modern industrial transmission systems, widely used in many fields due to its excellent performance and reliability. As a metal elastic element flexible coupling, it compensates for various deviations between shaft systems through the elastic deformation of multi-layer stainless steel diaphragm groups, achieving efficient and stable power transmission.

Double diaphragm coupling is a flexible coupling with multi-layer stainless steel diaphragm group as the core element, belonging to an advanced form of metal elastic element coupling. Through precise mechanical design and high-quality material application, various limitations of traditional couplings in complex working conditions have been solved.

The core structure of this coupling consists of two sets of metal diaphragms connected together by staggered bolts, forming an elastic deformation structure capable of withstanding complex loads. Metal diaphragms are usually made of high-strength stainless steel thin plates stacked in multiple layers. Each group of diaphragms is composed of several carefully designed thin plates stacked together. The shape of the diaphragms can be divided into two main types: linkage type and integral piece with different shapes. These membranes are processed with high precision and undergo special heat treatment processes to ensure their excellent mechanical properties and durability.

The working principle of the double diaphragm coupling is based on the elastic deformation characteristics of the metal diaphragm. When the active shaft rotates and transmits torque, the torque is first transmitted to the first set of diaphragms through the bolt group, causing precise elastic deformation of the diaphragms; Then, the torque is transmitted to the second set of diaphragms through the intermediate connection structure, ultimately reaching the driven shaft. During this process, if there is axial, radial, or angular relative displacement between the two axes, the diaphragm assembly can absorb and compensate for these deviations through its own elastic deformation, thereby ensuring the continuity and stability of power transmission.

Compared with traditional couplings, double diaphragm couplings have significant technical advantages. Firstly, it does not require any lubrication device, achieving oil-free transmission and avoiding problems of lubricant leakage and pollution. Secondly, the metal diaphragm has a compact structure, high strength, and can withstand extremely high torque loads, while also having a long service life. Furthermore, it has no rotational clearance, high transmission accuracy, and is not affected by temperature and oil pollution, making it capable of stable operation in harsh environments. In addition, the selection of stainless steel materials gives it excellent acid, alkali, and corrosion resistance, expanding its application range.

From the perspective of performance parameters, the double diaphragm coupling exhibits excellent engineering characteristics. Its static torsional stiffness is usually in the range of 450-3400N · m/rad, and suitable stiffness products can be selected according to different application requirements. In terms of speed adaptability, it can support high-speed operation up to 6000r/min, meeting the needs of most industrial equipment. The product series includes intermediate shaft types such as JMI, JMIJ, JMII, etc., which can achieve long wheelbase connection and automatically correct concentricity deviation, greatly simplifying the installation and debugging process.

Double diaphragm couplings have developed multiple models and series based on specific structures and application requirements, each with its unique performance characteristics and applicable scenarios. Understanding these types and their structural characteristics is crucial for the correct selection and application of double diaphragm couplings.

From an overall structural perspective, double diaphragm couplings are mainly divided into two categories: connecting rod diaphragm couplings and integral diaphragm couplings. The linkage type adopts multiple independent linkage shaped membranes distributed in a circular pattern, which has greater flexibility and can better compensate for complex deviations; The whole piece adopts a complete annular membrane structure, usually with higher torsional stiffness and load-bearing capacity. In practical applications, based on the differences in installation methods and usage requirements, the following common models of double diaphragm couplings have been developed:

JMI type diaphragm coupling: This is the most basic standard double diaphragm coupling, which adopts keyway connection method and is suitable for most conventional transmission occasions. Its characteristics are symmetrical structure, easy installation, and the ability to compensate for multiple types of shaft system deviations simultaneously. The JMI type has a wide range of static torsional stiffness, ranging from several hundred to several thousand N · m/rad, and users can choose the appropriate specifications according to the stiffness requirements of the transmission system.

JMIJ type diaphragm coupling: This model has been optimized based on JMI, enhancing the radial deviation compensation capability. It adopts a special membrane shape and arrangement, which enables the coupling to adapt to more demanding installation conditions, especially suitable for long wheelbase or transmission situations where precise alignment is difficult. JMIJ type typically has moderate torsional stiffness, balancing flexibility and transmission accuracy.

JMII type diaphragm coupling: This model is designed specifically for high-precision transmission systems, with extremely high torsional stiffness and positioning accuracy. The JMII type adopts high-strength materials and precision manufacturing processes to ensure the minimum torsional clearance and the highest dynamic response characteristics, and is widely used in precision machinery such as servo systems and CNC machine tools.

JMIIJ type diaphragm coupling: As an enhanced version of the JMII series, it maintains high stiffness while improving the deviation compensation capability through the improvement of the diaphragm group structure. This type of coupling is particularly suitable for high-end application scenarios that require both high transmission accuracy and certain installation deviations, such as aerospace, precision instruments, and other fields.

The core component of the double diaphragm coupling - the diaphragm group, whose design and manufacturing quality directly determine the performance of the coupling. The membrane is usually made of high-strength stainless steel (such as 304SS or 316SS) through a special heat treatment process, with a thickness generally between 0.2-0.5mm, and the number of stacking layers is determined according to the magnitude of the transmitted torque. The precision machined bolt holes and specially shaped elastic deformation zones on the membrane ensure uniform stress distribution when subjected to torque and compensating for deviations, avoiding early failure caused by local stress concentration.

The hub part of the coupling is usually made of high-quality alloy steel or aluminum alloy. Steel wheel hubs have higher strength and durability, making them suitable for heavy-duty applications; Aluminum alloy wheels, on the other hand, reduce the overall weight and are suitable for high-speed operation and applications that require reduced inertial loads. There are various connection methods between the wheel hub and the shaft, including keyway connection, clamping sleeve connection, cone sleeve connection, etc. Users can choose the most suitable type according to the characteristics of the equipment and installation conditions.

It is worth mentioning that the SJM double diaphragm coupling, as a special design model, demonstrates excellent performance parameters. It can operate stably in the extreme temperature range of -80~300 ℃, with a transmission efficiency of up to 99.86% and angular displacement compensation capability twice that of traditional gear couplings. This type of coupling adopts high-quality stainless steel thin plate multi-layer laminated diaphragm group, and is particularly suitable for harsh environments such as chemical pumps, aviation power systems, metallurgical equipment, etc. through optimized bolt interlocking connection method.

Compared with single diaphragm couplings, double diaphragm couplings have significantly improved performance. Due to structural limitations, single diaphragm couplings are not well suited for larger eccentric working conditions; The double diaphragm coupling, through the synergistic effect of two sets of diaphragms, can simultaneously undergo bending deformation in different directions, effectively compensating for more complex shaft system deviations. This structure enables the double diaphragm coupling to handle larger axial, radial, and angular displacements while maintaining higher transmission accuracy and stability.

As a key component in modern industrial transmission systems, the double diaphragm coupling exhibits a series of outstanding performance characteristics due to its unique structure and material properties, making it an ideal choice for many harsh working conditions. Understanding these technological advantages can help engineers fully leverage the potential of dual diaphragm couplings in equipment design and maintenance.

High precision compensation capability is one of the most prominent features of double diaphragm couplings. Compared with traditional gear couplings, the angular displacement compensation capability of double diaphragm couplings can be doubled, the reaction force generated during radial displacement is small, and the system flexibility is large. It can simultaneously compensate for three basic forms of displacement: axial, radial, and angular. The allowable axial displacement can usually reach ± 0.2-0.6mm, radial displacement 0.2-0.5mm, and angular displacement 0.5-1.5 degrees. This comprehensive compensation capability makes equipment installation and debugging more convenient, ensuring smooth operation even with some alignment errors, greatly reducing installation accuracy requirements and related costs.

In terms of vibration reduction and noise reduction, the double diaphragm coupling performs well. Its metal diaphragm structure has excellent elastic properties, which can effectively absorb and isolate vibrations and impacts in the transmission system, and operate without noise or wear. Test data shows that the double diaphragm coupling can significantly reduce the amplitude of system vibration, and in some applications, the vibration reduction can reach more than 30%. This characteristic makes it particularly suitable for precision mechanical transmission and applications with strict noise requirements, such as medical equipment, laboratory instruments, office machinery, etc. At the same time, the vibration reduction effect also extends the service life of supporting components such as bearings and seals, reducing overall maintenance costs.

Environmental adaptability is another major advantage of double diaphragm couplings. It is made of corrosion-resistant stainless steel material, which has excellent acid and alkali resistance and can resist the erosion of various corrosive media. The working temperature range is wide, and standard products can operate stably in environments ranging from -80 ℃ to+300 ℃. Specially designed models can even adapt to more extreme temperature conditions. Compared to couplings that require lubrication, the dual diaphragm design completely eliminates the need for lubrication, avoiding lubricant leakage and pollution issues, and meeting the requirements of modern industrial cleanliness and environmental protection. This strong adaptability makes it an irreplaceable choice in harsh working conditions such as chemical, marine, and metallurgical industries.

From the perspective of transmission efficiency, the double diaphragm coupling has almost achieved zero energy loss, with a transmission efficiency of up to 99.86%. The high efficiency is mainly due to the rigid connection characteristics of the metal diaphragm and the non-contact transmission principle, which eliminates the power loss caused by the friction pair in traditional couplings. In large industrial equipment and long-term continuous operation systems, this advantage can be translated into significant energy savings and reduced operating costs. Meanwhile, high transmission efficiency also means less heat generation, which helps maintain system stability and is particularly suitable for medium and high-speed high-power transmission scenarios.

The advantages in terms of structure and maintenance are equally noteworthy. The double diaphragm coupling has a compact structure and light weight, and compared to other types of couplings that transmit the same torque, its volume can be reduced by 20-30%. This compact design saves valuable installation space and is particularly suitable for applications with limited space. Its assembly and disassembly are extremely convenient, and products with intermediate shaft types can even complete assembly and disassembly operations without moving the machine, greatly simplifying maintenance procedures. Due to the absence of relatively sliding components and the characteristic of not requiring lubrication, the double diaphragm coupling has basically achieved maintenance free operation, reducing downtime and maintenance costs.

In terms of precise transmission, the double diaphragm coupling can accurately transmit speed and operate without slip, ensuring the synchronization and positioning accuracy of the transmission system. This feature makes it widely used in high-precision applications such as servo systems, stepper motor drives, encoder connections, etc. The coupling itself has no reverse clearance and excellent dynamic response characteristics, which can meet the demanding requirements of modern industrial equipment for motion control accuracy. Meanwhile, the double diaphragm coupling that has undergone dynamic balancing treatment can be applied to high-speed transmission shaft systems, with a maximum speed of 6000r/min or even higher, meeting the needs of high-speed equipment.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/double-diaphragm-coupling-exported-to-russia.html