The Flexible Plum Coupling is composed of two semi-couplings with convex claws and a plum-shaped flexible non-metallic element whose hardness can be adjusted. By embedding the plum-shaped flexible element into the two semi-couplings to realize the connection, it has the characteristics of compensating the relative displacement of the two axes, reducing vibration and buffering, simple structure and easy maintenance without lubrication.

Jaw Couplings generally consist of two hubs, and an elastomer element, known as a spider or cushion. Jaw Type Couplings connect the shaft of a motor, or moveable machine to the shaft on a stationary machine. Two jaws interlock around a jaw-coupling spider to create a complete coupling.

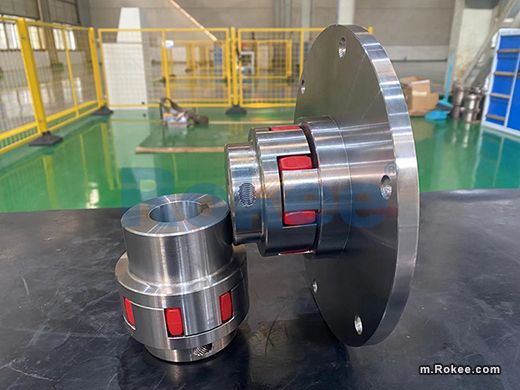

Model of Flexible Plum Jaw Couplings

- LM/ML Flexible Plum Jaw Coupling

- LMD/MLZ Flexible Plum Jaw Coupling With Single Flange

- LMS/MLS Flexible Plum Jaw Coupling With Double Flange

- LMZ-I/MLL-I Flexible Plum Jaw Coupling With Split Brake Wheel

- LMZ-II/MLL-II Flexible Plum Jaw Coupling With Integral Brake Wheel

- LMPK/MLPK Flexible Plum Jaw Coupling With Split Brake Disc

The plum blossom coupling consists of three parts:

- Metal claw plate: usually made of 45 steel or aluminum alloy material, and stainless steel is used in special occasions. The two claw plates are engaged by convex teeth, and their surfaces are precision machined through turning, milling, and overall heat treatment to enhance strength.

- Elastic element: located between two claw disks, mostly made of polyurethane or rubber material, with a plum blossom petal shape (commonly 4-10 petals). By transmitting torque through the compression deformation of elastic bodies, while compensating for axial, radial, and angular deviations.

- Fixed methods: including top screw fixation, clamping fixation, keyway fixation, and expansion sleeve connection, to meet different installation needs.

Working principle of jaw coupling

Utilizing elastic deformation to achieve power transmission, automatic compensation is achieved through elastic deformation when the shaft system deviates, and it also has the function of vibration reduction and buffering.

Dynamic performance:

- Compensation capability: capable of absorbing radial deviation (≤ 5mm), angular deviation (≤ 5 °), and axial displacement (± 1.5mm).

- Vibration reduction effect: The damping characteristics of elastic materials can reduce vibration amplitude by more than 30%, effectively protecting the transmission system.

- Speed range: allowable speed up to 30000r/min (depending on specifications), excellent balance performance.

Durability and environmental adaptability:

- Working temperature: -35 ℃ to+80 ℃, special materials can be extended to -50 ℃~+120 ℃.

- Maintenance free design: No lubrication required, resistant to oil stains and electrical insulation, with a lifespan of up to 10 years.

Structural advantages of claw coupling:

- Compact and lightweight: over 50% lighter than gear couplings, with small moment of inertia.

- No backlash design: The curved claw type (concave type) is suitable for servo systems, with a transmission accuracy of ± 0.02mm.

Main categories:

- Traditional straight claw type: Low cost, suitable for general transmission.

- Zero gap curved claw type: for high-precision applications (such as CNC machine tools and robots).

- Brake wheel type (LMZ series): Integrated braking function, used for lifting equipment.

- Split design (LMS type): The elastic body can be replaced without the need for a mobile device.

Application scenarios of plum coupling

- High precision equipment: CNC machine tools (spindle screw connection), semiconductor packaging machines.

- Heavy industry: metallurgical rolling mills, mining crushers.

- Energy sector: water pump units, wind power variable pitch systems.

- Automated production line: robot joints, packaging machinery.

Installation steps:

- Clean the shaft end and coupling inner hole, and apply lubricating grease.

- Use hot installation method or hydraulic tools for assembly, and prohibit violent tapping.

- Tighten the bolts in stages according to the diagonal sequence.

Failure prevention:

- Elastic body crushing: avoid overloading.

- Metal claw fracture: Regularly check the alignment accuracy.

- Risk of loosening: High speed equipment requires the use of anti loosening nuts, and the tightening force should be rechecked monthly.

Through reasonable selection and standardized installation, the plum blossom coupling can significantly improve the reliability of the transmission system, reduce maintenance costs, and is the preferred solution in the industrial transmission field.

In the realm of mechanical transmission systems, couplings serve as indispensable components that bridge rotating shafts, enabling the transfer of torque while accommodating various forms of misalignment. Among the diverse array of coupling types available, flexible couplings have gained widespread popularity due to their ability to mitigate the adverse effects of shaft misalignment, absorb vibration, and reduce noise—features that are critical for enhancing the reliability and longevity of mechanical equipment. Within the flexible coupling category, three distinct types stand out for their unique designs, performance characteristics, and application versatility: Flexible Plum Blossom Couplings, Elastic Claw Couplings, and Curved Jaw Couplings. Each of these couplings is engineered to address specific operational challenges, making them suitable for a wide range of industrial, automotive, and aerospace applications.

To understand the significance of these flexible couplings, it is first essential to recognize the fundamental challenges they are designed to overcome. In any rotating machinery, perfect alignment between connected shafts is nearly impossible to achieve, even with precise installation. Factors such as thermal expansion and contraction, manufacturing tolerances, bearing wear, and structural deformation can lead to three primary types of misalignment: angular misalignment (where the shafts intersect at an angle), parallel misalignment (where the shafts are offset parallel to each other), and axial misalignment (where the shafts move along their axial direction). Additionally, rotating systems often generate vibration and shock loads, which can cause excessive stress on shafts, bearings, and other components, leading to premature failure. Flexible couplings address these issues by incorporating elastic or flexible elements that can deform slightly to compensate for misalignment, absorb vibration, and dampen shock, thereby protecting the integrity of the transmission system. While all three coupling types—Flexible Plum Blossom, Elastic Claw, and Curved Jaw—fulfill this basic function, their distinct design configurations result in differences in torque capacity, misalignment compensation capabilities, vibration absorption performance, and suitability for specific operating conditions.

Starting with the Flexible Plum Coupling, this type derives its name from the plum blossom-shaped elastic element that serves as its core component. The basic structure of a Flexible Plum Blossom Coupling typically consists of two metal hubs with evenly spaced grooves on their opposing faces, and a plum blossom-shaped rubber or polyurethane insert that fits snugly into these grooves. The hubs are connected to the driving and driven shafts via keyways, set screws, or hydraulic expansion sleeves, ensuring a secure torque transfer interface. The plum blossom insert, often referred to as the "spider," is the critical flexible component that enables the coupling to accommodate misalignment and absorb vibration. Unlike rigid couplings, which transmit torque directly without any flexibility, the elastic spider in the Flexible Plum Blossom Coupling deforms elastically when the shafts are misaligned, allowing for angular, parallel, and axial compensation while maintaining a continuous torque transfer path.

The working principle of the Flexible Plum Blossom Coupling revolves around the elastic deformation of the spider. When torque is applied to the driving shaft, it is transmitted through the driving hub to the spider, which then transfers the torque to the driven hub and ultimately to the driven shaft. During this process, if the shafts are misaligned, the spider’s lobes (the "petals" of the plum blossom) deform slightly to bridge the gap between the misaligned hubs. This elastic deformation not only compensates for misalignment but also absorbs vibration and shock loads by converting kinetic energy into elastic potential energy, which is then dissipated as heat or returned to the system as the load fluctuates. The material selection for the spider is crucial to the performance of the coupling: rubber spiders offer excellent vibration absorption and flexibility but may have lower temperature and chemical resistance, while polyurethane spiders provide higher torque capacity, better wear resistance, and wider temperature tolerance, making them suitable for more demanding applications.

One of the key advantages of the Elastic Plum Coupling is its compact design and high torque density. The simple structure, consisting of only two hubs and a single spider, allows for a small radial and axial footprint, making it ideal for applications where space is limited. Additionally, this coupling type is easy to install and maintain—replacing the spider, which is the primary wear component, can be done quickly without disassembling the entire shaft system. Another notable advantage is its ability to operate quietly, as the elastic spider dampens the noise generated by shaft rotation and misalignment. However, the Flexible Plum Blossom Coupling does have limitations: its misalignment compensation capability is moderate compared to some other flexible coupling types, and the elastic spider is susceptible to aging and wear over time, especially in high-temperature or harsh chemical environments. Regular inspection and replacement of the spider are therefore necessary to ensure optimal performance and prevent unexpected failures.

Moving on to the Elastic Claw Coupling, this type is characterized by its claw-shaped hubs and elastic sleeves that connect the hubs. The structure of an Elastic Claw Coupling typically includes two metal hubs, each with several evenly distributed claw-like projections (or "teeth") on their mating surfaces. An elastic sleeve, usually made of rubber or polyurethane, is fitted over the claws of both hubs, creating a flexible connection between the driving and driven shafts. The elastic sleeve is often designed with a cylindrical or hexagonal cross-section, with internal grooves that match the shape of the hub claws, ensuring a secure fit and efficient torque transfer. Like the Flexible Plum Blossom Coupling, the Elastic Claw Coupling uses an elastic element (the sleeve) to accommodate misalignment and absorb vibration, but its claw-shaped design gives it distinct performance characteristics.

The working principle of the Flexible Claw Coupling is similar to that of the Flexible Plum Blossom Coupling, but with a focus on the interaction between the claw-shaped hubs and the elastic sleeve. When torque is transmitted from the driving shaft to the driving hub, the claws of the driving hub exert a force on the elastic sleeve, which in turn transfers the force to the claws of the driven hub, rotating the driven shaft. Misalignment between the shafts causes the elastic sleeve to deform locally—for angular misalignment, the sleeve bends slightly to accommodate the angle between the hubs; for parallel misalignment, the sleeve compresses on one side and stretches on the other; and for axial misalignment, the sleeve slides slightly along the claws. This deformation not only compensates for misalignment but also absorbs vibration and shock, reducing the stress on the shafts and bearings. The elastic sleeve also acts as a buffer, preventing direct metal-to-metal contact between the hubs, which helps to reduce wear and noise.

The Elastic Claw Coupling offers several unique advantages that make it suitable for a wide range of applications. One of its primary strengths is its excellent vibration absorption capability, thanks to the large contact area between the claw-shaped hubs and the elastic sleeve. This makes it particularly well-suited for applications with high vibration levels, such as electric motors, pumps, and compressors. Another advantage is its ease of assembly and disassembly—since the elastic sleeve can be easily slipped over the claws without the need for specialized tools, maintenance and replacement are straightforward. Additionally, the Elastic Claw Coupling is relatively cost-effective compared to more complex flexible coupling types, making it a popular choice for general industrial applications where high precision or extreme torque capacity is not required. However, like the Flexible Plum Blossom Coupling, the Elastic Claw Coupling has limitations: its torque capacity is lower than that of rigid or semi-rigid couplings, and the elastic sleeve is prone to wear, especially in applications with high torque or frequent start-stop operations. Furthermore, the claw-shaped design can lead to stress concentration in the hub claws if the coupling is subjected to excessive misalignment or shock loads, potentially reducing the service life of the hubs.

Next, the Curved Jaw Coupling is a variation of the Elastic Claw Coupling, distinguished by its curved (or arc-shaped) jaw profiles. While the Elastic Claw Coupling features straight or slightly tapered claws, the Flexible Jaw Coupling’s jaws are designed with a circular arc profile that mates with a corresponding curved elastic element. The structure of a Curved Jaw Coupling typically includes two metal hubs with curved jaws and a curved elastic spider (similar to the plum blossom insert but with curved lobes) that fits between the jaws. The curved design of the jaws and spider is engineered to improve the coupling’s performance by reducing stress concentration, increasing misalignment compensation capability, and enhancing torque transfer efficiency.

The working principle of the Elastic Jaw Coupling builds on the Elastic Claw Coupling but leverages the curved profiles to optimize force distribution. When torque is applied, the curved jaws of the driving hub exert a uniform force on the curved elastic spider, which then transfers the torque to the driven hub. The curved design allows for a larger contact area between the jaws and the spider compared to straight-jaw designs, resulting in more even stress distribution and reduced stress concentration. This not only increases the coupling’s torque capacity but also improves its ability to accommodate misalignment—especially angular misalignment. The curved spider also deforms more smoothly under load, providing better vibration absorption and shock damping compared to the straight elastic sleeves used in Elastic Claw Couplings. Additionally, the curved profile reduces the likelihood of the spider slipping or dislodging during operation, enhancing the coupling’s reliability.

The Metal Jaw Coupling offers several key advantages over both the Flexible Plum Blossom Coupling and the Elastic Claw Coupling. One of its most significant benefits is its superior misalignment compensation capability, particularly for angular misalignment. The curved jaws and spider allow for larger angular offsets without excessive stress on the coupling components, making it suitable for applications where shaft alignment is difficult to maintain, such as in agricultural machinery, construction equipment, and marine propulsion systems. Another advantage is its higher torque capacity and durability. The even stress distribution resulting from the curved profile reduces wear and fatigue on the hubs and spider, extending the coupling’s service life even in high-torque applications. Additionally, the Curved Jaw Coupling operates with minimal noise and vibration, thanks to the smooth deformation of the curved spider and the absence of sharp edges that can cause noise during operation. However, the Curved Jaw Coupling is generally more expensive than the Elastic Claw Coupling due to the more complex manufacturing process required for the curved jaws and spider. It also has a slightly larger radial footprint, which may limit its use in applications with extremely limited space.

To better understand the differences between these three coupling types, it is helpful to compare their key performance parameters. In terms of misalignment compensation, the Curved Jaw Coupling typically offers the highest angular misalignment capacity (up to 5 degrees or more, depending on the size), followed by the Flexible Plum Blossom Coupling (up to 3-4 degrees), and then the Elastic Claw Coupling (up to 2-3 degrees). For parallel misalignment, the Flexible Plum Blossom Coupling and Curved Jaw Coupling are relatively comparable (up to 0.5-1.5 mm), while the Elastic Claw Coupling may have a slightly lower capacity (up to 0.3-1.0 mm). Axial misalignment compensation is similar across all three types, ranging from 2-5 mm. In terms of torque capacity, the Curved Jaw Coupling generally has the highest torque rating, making it suitable for heavy-duty applications, while the Elastic Claw Coupling has the lowest torque capacity, ideal for light to medium-duty applications. The Flexible Plum Blossom Coupling falls in the middle, offering a balance of torque capacity and flexibility for medium-duty applications. Vibration absorption performance is also a key differentiator: the Curved Jaw Coupling provides the best vibration damping due to the smooth deformation of the curved spider, followed by the Flexible Plum Blossom Coupling, and then the Elastic Claw Coupling. Finally, in terms of cost, the Elastic Claw Coupling is the most economical, followed by the Flexible Plum Blossom Coupling, with the Curved Jaw Coupling being the most expensive.

The selection of the appropriate coupling type depends on a variety of factors, including the application’s torque requirements, misalignment conditions, operating environment, space constraints, and cost considerations. For light-duty applications with moderate vibration and minimal misalignment, such as small electric motors, fans, and pumps, the Elastic Claw Coupling is often the best choice due to its low cost, ease of maintenance, and adequate performance. For medium-duty applications that require a balance of flexibility, torque capacity, and compact design, such as in conveyors, packaging machinery, and textile equipment, the Flexible Plum Blossom Coupling is an excellent option. Its compact size and easy spider replacement make it a practical choice for these applications. For heavy-duty applications with significant misalignment, high torque, and harsh operating conditions, such as in construction machinery, agricultural equipment, marine systems, and industrial gearboxes, the Curved Jaw Coupling is the preferred choice. Its superior misalignment compensation, high torque capacity, and durability make it well-suited for these demanding environments.

Operating environment also plays a crucial role in coupling selection. For applications exposed to high temperatures (above 80°C), couplings with polyurethane or high-temperature rubber elements are preferred, as these materials offer better heat resistance than standard rubber. The Curved Jaw Coupling and Flexible Plum Blossom Coupling are often available with high-temperature spider options, making them suitable for high-temperature applications such as internal combustion engines and industrial furnaces. In applications where chemical exposure is a concern, such as in the chemical processing industry, couplings with chemical-resistant elastomers (such as nitrile rubber or fluororubber) should be selected. Additionally, in applications requiring clean operation, such as in the food and pharmaceutical industries, couplings with smooth surfaces and easy-to-clean components are ideal—both the Flexible Plum Blossom Coupling and Curved Jaw Coupling can be designed to meet these requirements.

Maintenance considerations are also important when selecting a coupling. All three coupling types require regular inspection to ensure the elastic elements are in good condition, as worn or damaged elastomers can lead to increased vibration, reduced misalignment compensation, and potential coupling failure. The Elastic Claw Coupling and Flexible Plum Blossom Coupling are relatively easy to maintain, as their elastic elements (sleeve or spider) can be replaced without disassembling the entire shaft system. The Curved Jaw Coupling, while more durable, may require more specialized tools for maintenance due to the tighter fit between the curved jaws and spider. Additionally, proper lubrication is not required for these coupling types, as the elastic elements act as self-lubricating components, reducing maintenance requirements compared to rigid couplings or couplings with rolling elements.

In recent years, advancements in material science and manufacturing technology have led to improvements in the performance and reliability of these three coupling types. For example, the development of high-performance polyurethane and composite materials has increased the torque capacity, temperature resistance, and wear resistance of the elastic elements, extending the service life of the couplings. Additionally, precision machining techniques, such as CNC milling and turning, have improved the dimensional accuracy of the hubs and elastic elements, ensuring better fit and more uniform force distribution. These advancements have expanded the application range of these couplings, allowing them to be used in more demanding environments and high-precision applications.

Looking to the future, the demand for flexible couplings is expected to grow as industries such as automotive, aerospace, and renewable energy continue to expand. In the automotive industry, the shift towards electric vehicles (EVs) has increased the need for compact, high-efficiency couplings that can accommodate the misalignment between the electric motor and transmission while absorbing vibration. The Flexible Plum Blossom Coupling and Curved Jaw Coupling are well-suited for these applications due to their compact design and excellent vibration absorption performance. In the aerospace industry, lightweight and high-strength couplings are required to reduce fuel consumption and improve aircraft performance. Advances in composite materials are enabling the development of lightweight versions of these couplings that meet the stringent requirements of the aerospace industry. In the renewable energy sector, wind turbines and solar tracking systems require couplings that can withstand harsh environmental conditions (such as high winds and temperature fluctuations) while accommodating significant misalignment. The Curved Jaw Coupling, with its superior misalignment compensation and durability, is particularly well-suited for these applications.

In conclusion, Flexible Plum Couplings, Elastic Claw Couplings, and Curved Jaw Couplings are essential components in modern mechanical transmission systems, each offering unique advantages that make them suitable for a wide range of applications. The Flexible Plum Blossom Coupling provides a balance of compact design, flexibility, and ease of maintenance, making it ideal for medium-duty applications. The Elastic Claw Coupling is a cost-effective option for light-duty applications with moderate vibration and misalignment. The Curved Jaw Coupling, with its superior misalignment compensation, high torque capacity, and durability, is the preferred choice for heavy-duty and demanding applications. When selecting a coupling, it is essential to consider factors such as torque requirements, misalignment conditions, operating environment, space constraints, and maintenance needs to ensure optimal performance and reliability. With ongoing advancements in materials and manufacturing technology, these coupling types will continue to evolve, playing an increasingly important role in the efficiency and reliability of mechanical systems across various industries.