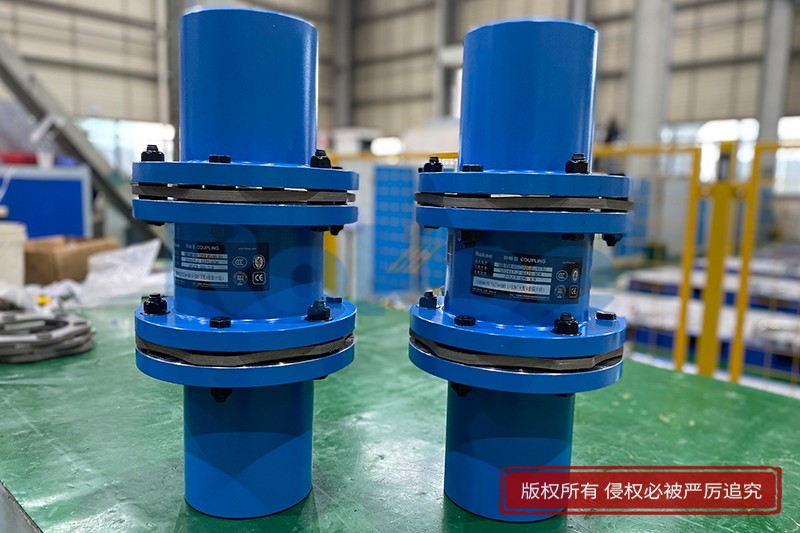

Rokee® Customized Metal Laminated Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

As a key component in modern mechanical transmission systems, metal laminated couplings play an important role in the industrial field due to their high precision, high torque transmission capability, and excellent compensation performance. The metal diaphragm coupling uses multi-layer metal elastic diaphragms as the core transmission component, and achieves torque transmission and deviation compensation between shaft systems through the elastic deformation of the diaphragms.

Core technology

Material and process: The mainstream materials used are 304/316 stainless steel or 45 grade steel film sheets, which have higher strength to weight ratios

Structural innovation: Modern designs often adopt porous laminated structures (mainly 6-8 holes), achieving force balance through symmetrical distribution of bolt groups

Connection methods: Developed various interface forms such as keyway type, expansion sleeve type (such as ZJM series), flange type, etc

Single membrane coupling

Representative models: DJM, JMII

Typical parameters: torque range 50-5000Nm, aperture 10-120mm

Advantages: Simple structure, low cost

Limitations: Compensation angle is generally ≤ 1 °

Double diaphragm coupling

Representative models: SJM, JMJ

Typical parameters: torque 200-20000Nm, compensation capacity axial ± 0.5mm/radial ± 1mm

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/metal-laminated-coupling.html