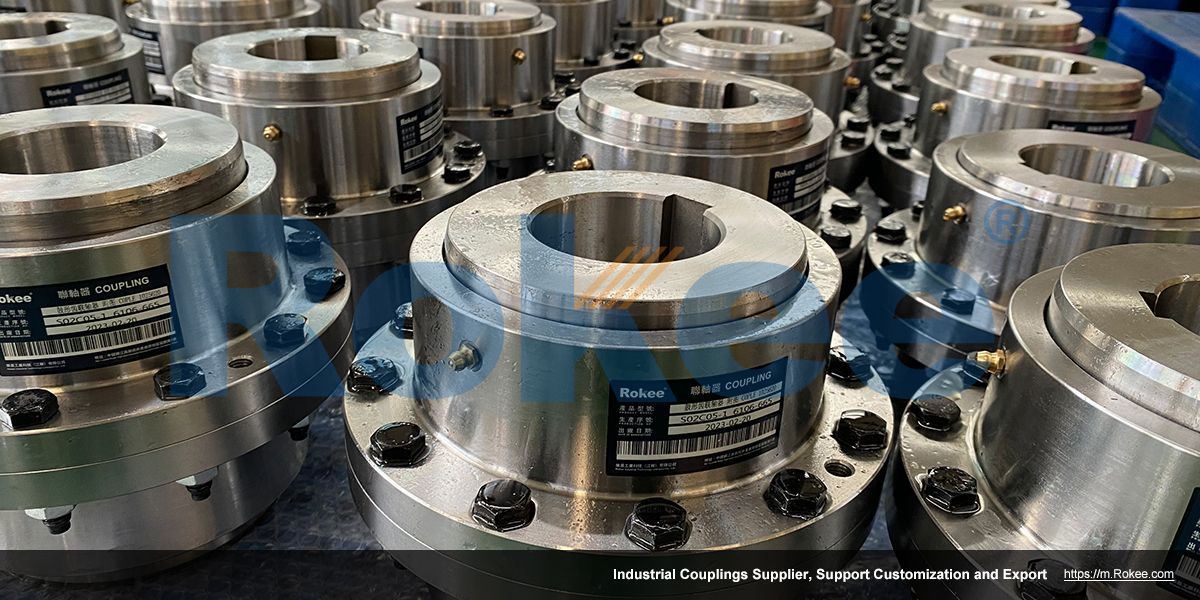

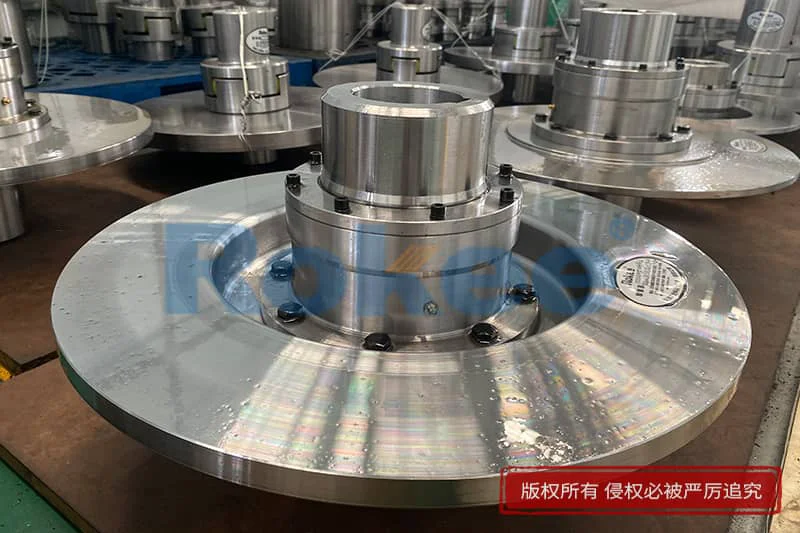

Rokee is a Drum Gear Coupling Supplier from china, Drum gear coupling belongs to a type of rigid flexible coupling. Its core structure mainly consists of an inner gear ring, an outer gear shaft sleeve (with a drum shaped tooth top and a circular arc shaped tooth surface), an end cap, and a sealing device. This special drum shaped design is a key feature that distinguishes it from other toothed couplings, giving the drum shaped toothed coupling unique performance and application advantages.

The working principle of Drum gear coupling is relatively simple and effective. During operation, the torque of the driving shaft is transmitted to the inner gear ring through the outer gear shaft sleeve, which in turn drives the driven shaft to rotate. Due to the presence of drum shaped teeth, when there is relative displacement between the two axes (such as angular displacement, radial displacement, and axial displacement), the contact point between the tooth surface of the drum shaped teeth and the tooth surface of the inner ring gear will change to adapt to this displacement. This displacement compensation capability enables the Drum gear coupling to maintain stable transmission performance under complex working conditions.

Performance characteristics

High torque transmission capability: The tooth profile design of the Drum gear coupling is reasonable, with a large contact area on the tooth surface, which can withstand large torque and is particularly suitable for heavy-duty transmission applications.

Good displacement compensation capability: The design of the drum shaped teeth enables the coupling to effectively compensate for angular displacement, radial displacement, and axial displacement between the two shafts, reduce additional loads caused by misalignment of the shaft system, and improve the reliability and service life of the equipment.

Smooth operation and low noise: The meshing process of the drum shaped teeth is relatively smooth, and compared to other couplings, the noise generated during operation is lower, making it suitable for work environments with strict noise requirements.

Easy installation and maintenance: The structure of the Drum gear coupling is relatively simple, and the alignment requirements for the two shafts during installation are not as strict as those for rigid couplings. At the same time, the sealing device is easy to replace, and the maintenance of internal components is also relatively convenient.

Drum gear couplings are widely used in multiple industrial fields due to their excellent performance:

Metallurgical industry: In large equipment such as rolling mills and blast furnaces, Drum gear couplings are used to connect motors and reducers, reducers and working machines, etc., to meet their heavy-duty and high impact working conditions.

Mining machinery, such as crushers, ball mills, and other equipment, work in harsh environments and are prone to shaft displacement. The Drum gear coupling, with its excellent displacement compensation capability and high reliability, ensures the stable operation of the equipment.

Petrochemical industry: Drum gear couplings are used to transmit power in equipment such as pumps and compressors. Its corrosion resistance and stable transmission performance ensure the continuity and safety of chemical production.

Power industry: Drum gear couplings are widely used in equipment such as steam turbine generators and fans, providing reliable power transmission for power production.

The manufacturing process of Drum gear couplings is constantly improving, using shell mold forming technology to reduce costs, and achieving separation and processing of inner and outer gear rings to improve accuracy. Some models are also equipped with forced thin oil lubrication system or segmented grease lubrication structure to reduce tooth wear and extend service life. For high-speed Drum gear couplings, lubricating oil is usually used for lubrication, and the smooth discharge of lubricating oil is ensured to avoid the rise of tooth surface temperature and the accumulation of water and dirt.

Drum gear couplings play an important role in many industrial fields due to their unique structure and excellent performance. With the continuous development of industrial technology, Drum gear couplings will also be upgraded and optimized to meet more complex and demanding working conditions.

« Drum Gear Coupling Supplier » Post Date: 2023/8/4

URL: https://m.rokee.com/blog/drum-gear-coupling-supplier.html

- What Are The Advantages Of Drum Gear Couplings

- What Does The Drum Gear Coupling Rely On For Transmission

- What Is The Dimension E In The Drum Gear Coupling

- What Is The Modulus Of The Drum Gear Coupling

- What Material Is The Drum Gear Coupling

- What Material Is Used For Drum Gear Couplings

- What Oil Is Added To The Drum Gear Coupling

- Drum Gear Coupling Housing

- Drum Gear Coupling Gear Module

- What Oil Is Used For Drum Gear Couplings